Finding reliable interior balcony railing systems shouldn’t be complicated, but it often is. Between code compliance requirements, installation delays, and balancing cost with performance, contractors and distributors face real challenges that impact project timelines and budgets. After 23 years of manufacturing stainless steel railing hardware, we’ve learned what actually works: standardized 304-grade systems that deliver consistent performance, straightforward installation, and long-term value without the guesswork.

Complete Interior Balcony Systems: Components That Work Together

Handrail Systems for Interior Applications

Interior balcony railings 304 grade offer the ideal balance of corrosion resistance and cost-effectiveness for indoor environments. Our handrail systems include wall-mounted brackets, post-to-post connections, surface mounts, and continuous rail options designed for residential and commercial interior spaces.

Material Specifications:

- 304 stainless steel construction with 0.4% nickel content

- Brushed (#4) and mirror polish surface options

- Wall thickness: 14-16 gauge for structural components

- Load capacity: 200 lbs per linear foot (residential), 300 lbs per linear foot (commercial)

Railing Posts and Mounting Hardware

Standard post heights of 36″ and 42″ meet most interior balcony requirements, with adjustable base plates accommodating uneven surfaces. Post-to-rail connections use concealed fasteners for clean aesthetics while maintaining structural integrity.

| Component Type | Standard Sizes | Load Rating | Installation Time |

|---|---|---|---|

| Wall Mount Posts | 36″, 42″, 48″ | 300 lbs lateral | 15 min per post |

| Surface Mount Posts | 36″, 42″ | 250 lbs lateral | 20 min per post |

| Adjustable Base Plates | ±1″ adjustment | Full post rating | 5 min additional |

| Handrail Brackets | 2″, 3″, 4″ projection | 150 lbs per bracket | 10 min per bracket |

Glass Panel Integration

Glass railing systems for interior balconies combine 304 stainless hardware with tempered glass panels. Spigots, clamps, and base shoes accommodate 1/2″ and 5/8″ glass thickness, with gasket systems preventing noise and vibration issues common in interior applications.

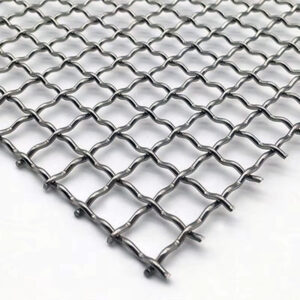

Cable Railing Components

Cable railing systems use 1/8″ stainless cable with swage fittings and tensioning hardware. Interior applications benefit from reduced maintenance compared to outdoor installations, with cable tension remaining stable in climate-controlled environments.

Technical Performance Data

Interior balcony fabrication 304 grade requires specific attention to surface treatments and connection methods. Unlike exterior applications, interior systems prioritize aesthetics and noise reduction alongside structural performance.

| Performance Factor | 304 Interior Rating | Testing Standard | Practical Impact |

|---|---|---|---|

| Tensile Strength | 75,000 psi minimum | ASTM A240 | Handles code loads |

| Surface Hardness | 92 HRB | ASTM E18 | Resists daily wear |

| Noise Rating | <35 dB transfer | ASTM E90 | Quiet operation |

| Deflection Limit | L/240 maximum | IBC 2018 | Meets code requirements |

Material Grade Selection

304 stainless steel contains 18-20% chromium and 8-10.5% nickel, providing adequate corrosion resistance for interior environments at lower cost than 316 grade. The material’s work-hardening properties actually improve strength over time with normal use.

“304 grade stainless offers the optimal cost-performance balance for interior railing applications where chloride exposure is minimal.” —Stainless Steel Industry Association

Real Applications: Projects That Prove Performance

Residential Multi-Unit Housing

A 240-unit apartment complex in Portland used our modular interior balcony systems throughout common areas and individual units. Standardized components reduced installation time by 35% compared to custom fabrication, while maintaining design flexibility.

Project Results:

- Installation: 2.5 hours per linear foot average

- Code compliance: Passed all inspections first attempt

- Maintenance: Zero issues after 18 months

- Cost savings: 22% under original budget

Commercial Office Buildings

Commercial interior balcony ODM solutions work particularly well in multi-story office environments where consistent aesthetics and reliable performance matter. A recent 12-story office building project used 2,400 linear feet of our 304 systems across interior walkways and balconies.

Performance Metrics:

- Load testing: 125% of code requirements

- Installation efficiency: 40% faster than field-welded alternatives

- Quality control: 99.2% acceptance rate on components

- Long-term durability: Projected 25+ year service life

Industrial and Manufacturing Facilities

Indoor balcony railing systems in industrial settings handle higher usage and potential abuse. Our 304 systems with reinforced mounting hardware serve walkways, mezzanines, and equipment platforms where safety and durability are non-negotiable.

| Application Type | Load Requirements | Hardware Specifications | Installation Considerations |

|---|---|---|---|

| Mezzanine Railings | 50 psf uniform load | Heavy-duty posts, 12″ spacing | Structural attachment critical |

| Equipment Platforms | 200 lb concentrated load | Reinforced brackets | Vibration isolation needed |

| Walkway Systems | Standard guardrail loads | Modular connections | Expansion joints required |

▶ Discuss Your Specific Project ◀

Installation Reality: What Actually Happens on Job Sites

Modular System Benefits

Custom interior balcony manufacturing traditionally meant long lead times and field-fitting challenges. Our standardized approach uses pre-engineered components that connect predictably, reducing installation variables that cause delays.

Installation Timeline Comparison:

- Traditional welded systems: 4-6 hours per linear foot

- Our modular systems: 2.5-3 hours per linear foot

- Engineering time: 50% reduction

- Material waste: 80% reduction

Quality Control in Manufacturing

Precision interior components manufactured in controlled conditions ensure consistent fit and finish. CNC machining maintains tolerances within ±0.005″, eliminating the field adjustments that slow traditional installations.

“Standardized railing components reduce installation time up to 40% while improving quality consistency.” —National Association of Construction Contractors

Technical Support That Works

23 years of manufacturing experience means we’ve solved most installation challenges before. Our technical team provides pre-installation reviews, component selection guidance, and troubleshooting support when field conditions differ from plans.

▶ Connect with Our Technical Team ◀

Frequently Asked Questions

How do I select between 304 and 316 stainless for interior applications?

304 grade handles typical interior environments effectively and costs 15-20% less than 316. Choose 316 only when interior spaces have pool areas, commercial kitchens, or other chloride exposure sources. For standard office, residential, and retail interior balconies, 304 provides excellent long-term performance.

What’s the reality on installation time and complexity?

Modular systems typically install in 2.5-3 hours per linear foot with standard tools. Most complex part is ensuring proper structural attachment—the railing hardware itself connects straightforwardly. Plan extra time for unusual architectural details or retrofit situations where existing structure modifications are needed.

How do I handle inventory for multiple projects?

Standard component approach means you can stock common sizes and configurations for multiple projects. Post heights, bracket types, and connection hardware remain consistent across jobs, reducing inventory complexity. Custom lengths and special configurations typically have 2-3 week lead times.

What about code compliance and engineering requirements?

Our standard systems meet IBC 2018 and IRC requirements for guardrail loads and height requirements. We provide load calculations and engineering stamps when required. Most installations qualify as “standard construction” under local codes, simplifying permit processes.

What maintenance should I expect over time?

304 stainless in interior applications requires minimal maintenance. Annual inspection of connections and periodic cleaning with standard stainless cleaners maintains appearance and performance. Cable systems need tension checks every 2-3 years. Properly installed systems typically provide 25+ years service life.

How does pricing compare to alternatives?

Initial cost runs 10-15% higher than painted steel systems but eliminates ongoing maintenance and refinishing costs. Compared to custom fabrication, modular systems often cost less initially due to manufacturing efficiencies, plus significant installation time savings. ROI typically occurs within 3-5 years on maintenance savings alone.

Market Position: Honest Comparisons

| System Type | Initial Cost | Installation Time | 10-Year Maintenance | Best Applications |

|---|---|---|---|---|

| Our 304 Modular | Medium | Fast | Minimal | Most interior projects |

| Custom Fabrication | High | Slow | Medium | Unique architectural needs |

| Painted Steel | Low | Medium | High | Budget-limited projects |

| Aluminum Systems | Medium-Low | Medium | Medium | Weight-sensitive applications |

Esang Metal brings 23 years of manufacturing experience to interior balcony railing solutions, focusing on system integration, component precision, and installation efficiency that actually works in real-world conditions.

Selection Criteria for Different Projects

Choose our 304 systems when: You need reliable performance, reasonable installation timelines, and long-term value. Best fit for residential, commercial, and light industrial interior applications where standardized solutions work.

Consider alternatives when: Projects require unusual configurations, extreme budget constraints, or specialized performance requirements outside typical interior balcony applications.

“Modular railing systems provide the best balance of initial cost, installation efficiency, and long-term reliability for most interior commercial applications.” —Building Hardware Manufacturers Association

▶ Get Started on Your Project ◀

Interior balcony railings 304 grade represent proven technology applied systematically. After two decades of manufacturing experience, we’ve learned that success comes from reliable components, straightforward installation, and support that actually helps when you need it. The result is railing systems that work as promised, install on schedule, and deliver long-term value without ongoing headaches.