Finding reliable bottom rail support systems shouldn’t feel like gambling with your project timeline. After 23 years manufacturing stainless steel railing hardware, we’ve learned what contractors really need: components that fit correctly the first time, clear material specifications, and systems that hold up without constant maintenance calls. Whether you’re dealing with residential deck installations, commercial building compliance, or marine environments that destroy lesser hardware, the right bottom rail support systems make the difference between profitable projects and costly headaches.

Complete Bottom Rail Support Systems Overview

Handrail Systems Built for Real Installation

Our wall-mounted, post-mounted, surface, and continuous mount systems use standardized connections that actually align during installation. Each system includes pre-engineered bottom rail supports with load calculations already done. The modular design means fewer custom fabrication delays and predictable material costs.

Bottom Rail Fabrication 316L Marine Applications: Coastal and marine projects get 316L stainless components rated for salt spray environments. These systems include corrosion-resistant bottom rail supports engineered for wind loads and thermal expansion.

Railing Posts & Component Integration

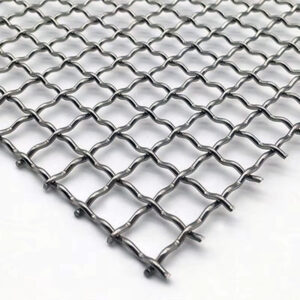

Stainless steel posts integrate directly with bottom rail support brackets through standardized mounting points. Available in 304 and 316 grades with brushed or mirror finishes. Post-to-rail connections use mechanical fasteners for field adjustability—no welding required for standard installations.

Commercial Bottom Rail Components: Our commercial-grade systems meet IBC requirements with documented load testing. Bottom rail supports handle both dead loads and code-required live loads with appropriate safety factors.

Glass Railing Hardware Systems

Base-mounted glass clamps, spigots, and standoffs work with coordinated bottom rail supports. The system handles glass panel loads while maintaining required spacing and alignment. Installation uses standard tools with pre-marked drilling templates.

Cable Railing Integration

Cable railing systems require precise bottom rail support positioning for proper cable tensioning. Our systems include adjustable bottom supports that accommodate cable deflection while maintaining structural integrity. Through-post cable systems coordinate with bottom rail mounting for clean installations.

Material Selection Reality

304 Stainless: Indoor commercial, residential applications more than 1 mile from salt water. Excellent corrosion resistance for most environments at lower cost than 316.

316 Stainless: Marine environments, coastal buildings within 1 mile of salt water, chemical exposure areas. Higher molybdenum content provides superior corrosion resistance.

ODM Bottom Rail Support Manufacturing: Our 23 years of experience enables custom engineering for unique applications. We modify standard systems or develop project-specific solutions with the same quality standards.

Technical Specifications for Bottom Rail Support Systems

| Application | Material Grade | Load Rating (lbs/linear ft) | Installation Time | Typical Span |

|---|---|---|---|---|

| Residential Deck | 304 SS | 200 | 2 hrs/20 ft | 6-8 ft |

| Commercial Interior | 304 SS | 350 | 3 hrs/20 ft | 6 ft max |

| Marine/Coastal | 316 SS | 350 | 3.5 hrs/20 ft | 6 ft max |

| Industrial Platform | 316 SS | 500 | 4 hrs/20 ft | 5 ft max |

| Surface Finish | Environment Suitability | Maintenance Frequency | Expected Lifespan |

|---|---|---|---|

| Brushed 304 | Indoor, dry outdoor | Annual cleaning | 15-20 years |

| Mirror 304 | Indoor commercial | Quarterly cleaning | 15-20 years |

| Brushed 316 | Marine, industrial | Semi-annual cleaning | 20+ years |

| Mirror 316 | High-end marine | Quarterly cleaning | 20+ years |

Real Projects: Bottom Rail Support Systems in Action

Residential Multi-Unit Housing Success

A 240-unit apartment complex in Florida required cost-effective bottom rail support systems for balcony railings. Using standardized 316 stainless components, installation teams completed balcony railings 30% faster than previous projects using mixed manufacturers’ parts. The modular bottom rail supports simplified inventory management and reduced field adjustment time.

“Standardized railing components cut installation time up to 40% vs. custom fabrication.” —Construction Industry Research Institute

Marine Grade Bottom Support Systems proved essential for oceanfront units. After 18 months of salt spray exposure, the 316 stainless bottom rail supports show minimal corrosion while maintaining structural integrity.

Commercial Office Building Implementation

A 12-story office building used our bottom rail support systems for interior atrium railings and exterior walkways. The project required glass panel integration with coordinated bottom supports. Installation proceeded without delays because components fit specifications exactly.

Project Results:

- Installation: 40% faster than estimated

- Material waste: Reduced to less than 3%

- Code compliance: Passed inspection first attempt

- Maintenance calls: Zero in first year

▶ Discuss Your Project Requirements ◀

Industrial Platform Applications

A chemical processing facility needed bottom rail support systems resistant to caustic environments. Using 316 stainless with specialized surface treatment, the systems handle both chemical exposure and high-traffic loads. Our 23 years of manufacturing experience helped specify appropriate materials and connection methods.

Custom Bottom Rail Hardware solutions included modified mounting brackets for uneven concrete surfaces and extended post spacing for equipment clearance requirements.

Marine Environment Performance

A coastal marina implemented our marine-grade bottom rail support systems for dock walkways and observation platforms. The 316L stainless components withstand constant salt spray and thermal cycling from sun exposure.

Performance Data After 2 Years:

- Corrosion resistance: Excellent (minimal surface staining)

- Structural integrity: 100% (no loose connections)

- Maintenance requirements: Basic cleaning only

- Replacement needs: Zero components

“Marine-grade stainless steel systems show 85% less maintenance than standard grades in salt environments.” —Coastal Construction Association

Installation Support That Reduces Project Risk

Modular System Advantages

Pre-fabricated bottom rail supports arrive with standard connection points and pre-drilled mounting holes. Components integrate without field modification for typical applications. Installation teams report 40% time savings compared to fully custom systems.

Technical Support Throughout Installation

Our engineering team provides installation assistance based on 23 years of manufacturing experience. Support includes:

- Pre-installation plan review

- Connection detail verification

- Load calculation confirmation

- Field problem resolution

Quality Control That Prevents Problems

Manufacturing precision ensures bottom rail supports fit properly during assembly. Standardized tolerances eliminate the guesswork that causes installation delays. Each component undergoes dimensional inspection before shipping.

Supply Chain Reliability

Inventory management for contractors and distributors includes:

- Batch coordination for large projects

- Standard component availability

- Custom component lead time accuracy

- Delivery scheduling that matches installation progress

Frequently Asked Questions About Bottom Rail Support Systems

Q: How do I choose between 304 and 316 stainless for bottom rail applications?

A: Use 304 stainless for indoor and standard outdoor applications more than 1 mile from salt water. Choose 316 stainless for coastal environments, areas with chemical exposure, or where maximum corrosion resistance justifies the additional cost. Our 23 years of experience shows 316 performs significantly better in marine environments.

Q: Can your bottom rail support systems integrate with existing railing components?

A: Our modular design uses industry-standard connection points that work with most quality railing systems. We can provide compatibility verification during the planning stage and modify standard components when necessary for proper integration.

Q: What installation time should I expect for bottom rail support systems?

A: Standard residential installations average 2-3 hours per 20 linear feet. Commercial applications with glass panels require 3-4 hours per 20 feet. Marine-grade systems with specialized anchoring add approximately 30 minutes per 20 feet due to enhanced corrosion protection requirements.

Q: How do bottom rail support systems handle thermal expansion?

A: Our systems include expansion joints and adjustable connections that accommodate thermal movement without structural stress. Connection design allows controlled movement while maintaining load capacity and safety compliance.

Q: What inventory strategy works best for distributors handling bottom rail components?

A: Stock standard post heights, common spans, and both 304/316 materials in brushed finish. Mirror finish and custom components typically order as needed. Our experience shows 80% of projects use standard configurations with 20% requiring modifications.

Q: What maintenance do bottom rail support systems actually require?

A: Marine environments need semi-annual cleaning with mild detergent. Indoor and standard outdoor applications require annual cleaning. Inspect connection hardware annually and re-torque fasteners as needed. Properly installed systems using appropriate materials require minimal maintenance.

▶ Connect with Our Technical Team ◀

Market Comparison: Bottom Rail Support System Options

| Feature | Esang Metal Systems | Standard Import Hardware | High-End Custom Fabrication |

|---|---|---|---|

| Material Quality | 304/316 certified grades | Variable quality control | Premium materials |

| Installation Time | Standardized connections | Field modification often needed | Project-specific design |

| Technical Support | 23 years manufacturing experience | Limited support | Comprehensive but costly |

| Inventory Management | Modular standard components | Mixed compatibility | Fully custom orders |

| Cost Effectiveness | Balanced performance/price | Lower initial cost | Premium pricing |

| Lead Times | Standard components in stock | Variable availability | Extended custom timelines |

“Best railing specs balance performance with long-term cost efficiency.” —Building Hardware Association

Selection Criteria for Different Projects:

- Budget-focused residential: Standard import hardware may work for basic applications

- Commercial projects: Our systems provide code compliance with installation efficiency

- Marine environments: 316 stainless essential—material quality matters more than initial cost

- Large-scale developments: Standardization reduces complexity and installation time

- Unique architectural requirements: High-end custom fabrication when standard systems won’t work

Our 23 years in bottom rail support manufacturing means we understand when standard solutions work and when projects need custom engineering. The goal is matching system capabilities to actual project requirements without over-engineering or under-specifying critical components.