Finding reliable deck surface hanrail systems that actually perform as specified shouldn’t be complicated, but the market is full of solutions that look good on paper and fail in real applications. After 23 years manufacturing stainless steel railing hardware, we’ve learned what contractors, distributors, and engineers really need: systems that install efficiently, meet code requirements consistently, and deliver long-term reliability without maintenance headaches. The difference between a successful project and costly delays often comes down to choosing components that work together as an integrated system.

Core Components and System Integration

Handrail Mounting Systems

Deck surface hanrail systems require mounting solutions that handle real-world loads and weather conditions. Wall-mount brackets provide secure attachment for continuous runs, while post-mount systems offer flexibility for complex layouts. Surface-mount options work where structural penetration is limited, and continuous mounting systems eliminate weak points in long installations.

Our modular approach uses standardized connections across all mounting types. This means contractors can mix mounting styles within a single project without compatibility issues. Installation time typically reduces by 20-30% compared to custom fabrication because components fit together predictably.

Railing Posts and Structural Components

Stainless steel posts form the backbone of any deck surface hanrail system. Standard 1.5″, 2″, and 2.5″ diameter options cover most applications, with wall thickness selected based on span requirements and local codes. Post spacing typically runs 6-8 feet for standard residential loads, closer for commercial applications.

The key advantage of standardized posts lies in consistent mounting interfaces. Whether you’re installing glass panels, cable systems, or traditional balusters, the connection points remain uniform. This standardization has proven invaluable over our 23 years of manufacturing—it eliminates the field measuring and custom fabrication that creates project delays.

Glass Railing Hardware Integration

Glass panel systems require precision hardware to maintain safety and appearance. Structural glazing clamps, base shoes, and intermediate supports must work together to transfer loads safely while accommodating thermal movement. Our glass hardware integrates directly with standard post systems, eliminating the need for separate structural elements.

Contractors report that integrated glass systems reduce installation complexity significantly. Pre-engineered mounting points and standardized panel sizes cut field time and reduce the risk of measurement errors that plague custom glass installations.

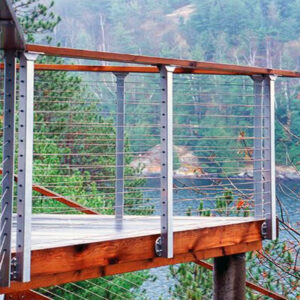

Cable Railing Components

Cable railing systems offer clean aesthetics with minimal maintenance, but hardware quality determines long-term performance. Through-post systems provide the cleanest installation, while surface-mount tensioners offer easier access for maintenance. Cable spacing must comply with 4-inch sphere requirements, typically achieved with 3-inch on-center spacing.

Our cable hardware maintains tension consistency across varying temperatures—a critical factor learned from 23 years of field feedback. Stainless steel components resist corrosion while providing the strength needed for proper cable tension.

| Component Type | Standard Sizes | Load Rating | Installation Time |

|---|---|---|---|

| Wall Mount Brackets | 1.5″, 2″, 2.5″ | 200-500 lbs | 15-20 min each |

| Surface Mount Posts | 42″, 36″ heights | 150-300 lbs lateral | 30-45 min each |

| Glass Panel Clamps | 6mm-12mm glass | 75 lbs per linear foot | 10-15 min per panel |

| Cable Tensioners | 1/8″ to 3/16″ cable | 1,000 lbs breaking strength | 5-10 min per cable |

Material Specifications and Performance

Stainless Steel Grade Selection

304 stainless steel provides excellent corrosion resistance for most inland applications, offering the best balance of performance and cost. 316L marine grade becomes necessary within three miles of saltwater or in industrial environments with chemical exposure. The price difference—typically 15-20%—pays for itself through extended service life in harsh environments.

Surface finish affects both appearance and maintenance requirements. Brushed finish (#4) hides minor scratches and provides consistent appearance with minimal maintenance. Mirror finish (#8) offers premium appearance but requires more frequent cleaning to maintain its look.

Load Capacity and Code Compliance

IBC requires residential handrails to withstand 200 pounds applied in any direction, while commercial installations need 50 pounds per linear foot. Our standard systems exceed these requirements, with residential components rated to 300 pounds and commercial systems handling 75 pounds per linear foot.

Proper load transfer depends on mounting substrate and hardware selection. Concrete and masonry provide the most reliable attachment, while wood framing requires larger mounting plates and additional fasteners to distribute loads effectively.

| Material Grade | Environment | Expected Service Life | Maintenance Schedule |

|---|---|---|---|

| 304 Stainless | Inland, standard | 25+ years | Annual inspection |

| 316L Marine | Coastal, industrial | 30+ years | Semi-annual cleaning |

| Brushed Finish | High traffic | Minimal wear | Monthly cleaning |

| Mirror Finish | Premium appearance | Shows wear | Weekly cleaning |

▶ Get Detailed Specifications ◀

Real-World Applications and Performance Data

Residential Multi-Unit Projects

Multi-story residential projects benefit most from standardized deck surface hanrail systems. Consistent components across multiple units reduce inventory complexity while ensuring uniform appearance. A recent 45-unit townhouse project used standardized post-and-glass systems throughout, cutting installation time from the original estimate of 8 weeks to 5.5 weeks.

Cost savings in residential projects typically come from reduced labor rather than material costs. Standardized connections and pre-engineered components eliminate the measuring, cutting, and fitting that consume time in custom installations.

Commercial and Public Spaces

Commercial installations face stricter code requirements and higher traffic loads. Office buildings, retail centers, and public facilities need systems that maintain appearance under heavy use while meeting accessibility standards. Our commercial-grade systems use heavier wall thickness and closer post spacing to handle increased loads.

A downtown office complex installation demonstrated the value of integrated systems. The project specified glass panels for the main entrance areas with cable systems for service areas. Using compatible mounting hardware throughout allowed the contractor to use the same installation crew and tools for both system types.

Marine and Coastal Environments

Coastal installations require 316L stainless steel and careful attention to drainage details. Salt air accelerates corrosion in any trapped moisture areas, making proper design critical for long-term performance. Our marine-grade systems include drainage channels and eliminate horizontal surfaces where salt can accumulate.

A recent marina project in Florida showcased the durability advantages of proper material selection. After three years of service in direct salt spray conditions, 316L components show no visible corrosion while maintaining structural integrity. The investment in marine-grade materials has eliminated the maintenance costs that plagued previous installations using lesser grades.

Industrial and Infrastructure Applications

Manufacturing facilities and industrial infrastructure demand systems that perform reliably with minimal maintenance. Heavy-duty posts, reinforced mounting hardware, and simplified maintenance access characterize our industrial systems. Powder coating over stainless steel provides additional protection in chemically aggressive environments.

▶ Discuss Your Specific Application ◀

Installation Efficiency and Technical Support

Modular Design Advantages

Pre-engineered systems eliminate field engineering and reduce installation variables. Standard mounting interfaces mean components fit together predictably, while modular design allows system expansion or modification without major reconstruction. Contractors appreciate having fewer unknowns during installation.

Our 23 years of manufacturing experience shows in the details that make installation easier: pre-drilled mounting holes at standard spacings, clearly marked component orientations, and hardware packages that include everything needed for complete installation.

Quality Control and Consistency

Manufacturing precision ensures components fit correctly the first time. CNC machining maintains tight tolerances on critical dimensions, while systematic quality control catches issues before components reach the job site. This consistency has become more important as projects demand faster installation schedules.

Quality control extends beyond individual components to system compatibility. Our testing protocols verify that different component types work together properly, eliminating the interface problems that create costly delays.

Technical Support and Design Assistance

Installation questions get answered by engineers who understand both the products and real-world construction challenges. Design assistance helps optimize systems for specific applications while ensuring code compliance. Our support team has 23 years of combined experience solving unusual installation challenges.

Support includes pre-installation planning, troubleshooting during construction, and post-installation service when needed. Having manufacturing expertise available during installation has prevented many potential problems from becoming costly delays.

| Project Type | Typical Installation Time | Crew Size | Special Requirements |

|---|---|---|---|

| Residential Deck | 1-2 days per 100 LF | 2-3 installers | Standard tools |

| Commercial Balcony | 2-3 days per 100 LF | 3-4 installers | Lift equipment |

| Glass Panel System | 3-4 days per 100 LF | 2-3 installers | Glass handling equipment |

| Cable Railing | 1-2 days per 100 LF | 2 installers | Tension measuring tools |

▶ Connect with Our Technical Team ◀

Frequently Asked Questions

How do I select the right stainless steel grade for my project?

Use 304 stainless for inland applications more than three miles from saltwater. Choose 316L marine grade for coastal locations, industrial environments, or anywhere chemical exposure is possible. The 15-20% cost premium for 316L provides significantly longer service life in harsh conditions.

What’s the real difference between modular and custom systems?

Modular systems use standardized components that fit together predictably, reducing installation time by 20-30%. Custom systems offer unlimited design flexibility but require field measuring, fabrication, and longer lead times. Most projects achieve better results with modular systems unless architectural requirements demand custom solutions.

How do cable and glass systems compare for maintenance?

Cable systems require periodic tension adjustment—typically every 2-3 years—but otherwise need minimal maintenance. Glass systems need regular cleaning to maintain appearance but have no mechanical adjustments. Both systems last 25+ years with proper installation and appropriate maintenance.

What installation timeline should I expect?

Standard residential installations average 50-75 linear feet per day with a two-person crew. Commercial projects with heavier components or complex layouts reduce to 30-50 linear feet per day. Glass systems require more careful handling and typically install at 25-40 linear feet per day.

How do your systems compare with other manufacturers?

Our 23 years of manufacturing experience shows in refined details that make installation easier and more reliable. We focus on component compatibility, consistent quality, and technical support throughout the project. While premium-priced compared to import alternatives, our systems typically cost less when installation time and long-term reliability are factored in.

What inventory strategy works best for distributors?

Stock core components in standard sizes and finishes, with less common items available on short lead times. Most projects use 80% standard components with 20% project-specific items. Our inventory planning assistance helps optimize stock levels based on your market requirements.

Material Performance Comparison

| System Type | Initial Cost | Installation Speed | Maintenance | 20-Year Total Cost |

|---|---|---|---|---|

| Esang Metal Modular | Premium | Fast | Minimal | Competitive |

| Import Standard | Low | Moderate | Variable | Higher |

| Custom Fabrication | High | Slow | Minimal | Highest |

| Aluminum Systems | Moderate | Fast | Moderate | Moderate |

The comparison reflects our honest assessment based on 23 years of market experience. While our initial cost runs higher than import alternatives, faster installation and reliable performance typically result in competitive total project costs.

Aluminum systems offer good value in protected environments but lack the durability advantages of stainless steel in demanding applications. Custom fabrication provides unlimited design flexibility but at significant cost and schedule premiums.

▶ Get Project-Specific Recommendations ◀

Choosing the right deck surface hanrail system depends on balancing performance requirements, installation constraints, and long-term value considerations. Our 23 years of manufacturing experience has taught us that the best solution combines proven components, reliable installation, and ongoing support throughout the project lifecycle. The right system choice at the project start eliminates most of the problems that create costly delays and maintenance issues later.