After 23 years in the stainless steel hardware business, we’ve learned that most railing failures start at the foundation. Contractors call us when standard mounting hardware fails inspections, delays projects, or creates maintenance headaches down the road. Heavy duty base plates solve these problems by providing engineered mounting solutions that meet codes the first time and stay reliable for decades. Esang Metal has developed comprehensive base plate systems that work across residential, commercial, industrial, and marine applications—because your project timeline depends on hardware that performs as specified.

Heavy Duty Base Plate Systems & Components

Core Base Plate Configurations

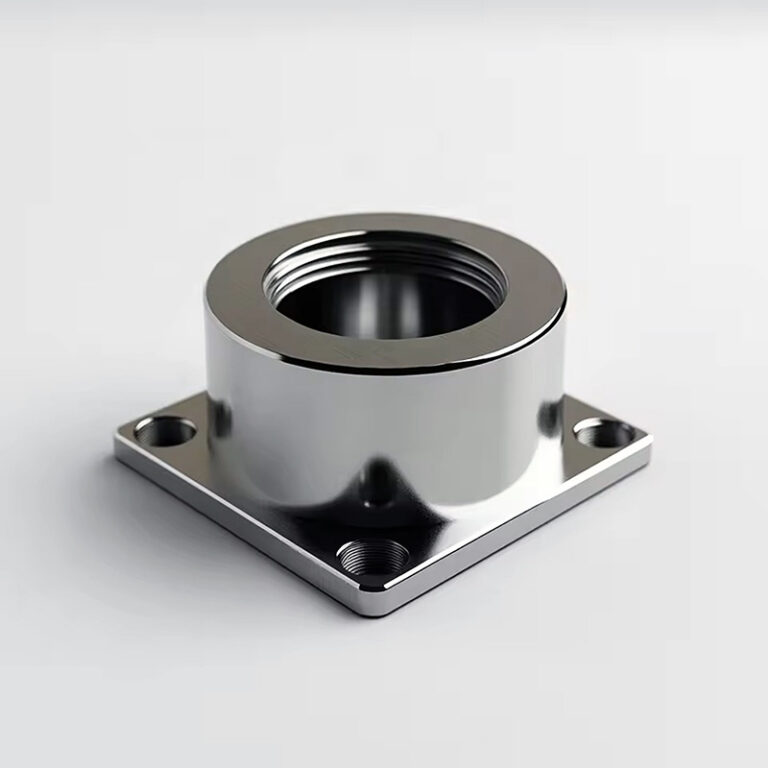

Surface Mount Base Plates handle the majority of commercial and residential installations where concrete or structural steel provides solid attachment points. These plates distribute loads across wider areas, reducing stress concentrations that cause premature failures. Standard configurations include 4-bolt, 6-bolt, and 8-bolt patterns with engineered load ratings.

Embedded Base Plates solve new construction challenges where posts need integration with concrete pours. Pre-positioned anchor systems ensure accurate placement and eliminate field drilling errors that delay projects. Galvanic isolation treatments prevent corrosion at concrete interfaces.

Adjustable Height Base Plates compensate for construction tolerances without custom fabrication delays. Threaded adjustment systems handle up to 2-inch variations while maintaining structural integrity. Contractors report 30-40% faster installation compared to shimming standard plates.

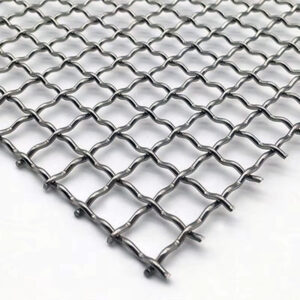

Marine Grade Heavy Duty Mounting uses 316L stainless construction with enhanced corrosion resistance for coastal and industrial environments. These systems handle salt spray, chemical exposure, and thermal cycling that destroys standard hardware within years.

Material Engineering That Matters

304 Stainless Steel provides cost-effective performance for most commercial applications. Tensile strength exceeds 75,000 PSI with excellent forming characteristics for complex geometries. Interior applications typically see 20+ year service life with minimal maintenance.

316L Stainless Steel adds molybdenum for superior corrosion resistance in harsh environments. Chemical processing, marine installations, and coastal properties require this upgrade. The material premium pays for itself through reduced replacement costs.

Surface Treatment Options include brushed finishes for durability and mirror polish where appearance matters. Passivation treatment activates the protective oxide layer, extending service life in contaminated environments.

Heavy Duty Base Plate Fabrication 316L involves precision machining and welding processes that maintain material properties throughout manufacturing. Heat treatment controls grain structure for optimal strength and corrosion resistance.

▶ Get Technical Specifications ◀

Load Capacity & Performance Data

| Base Plate Type | Material Grade | Bolt Pattern | Vertical Load (lbs) | Moment Capacity (ft-lbs) | Typical Application |

|---|---|---|---|---|---|

| Standard Surface | 304 SS | 4-bolt 4″ x 4″ | 2,500 | 1,200 | Residential, Light Commercial |

| Heavy Duty Surface | 316L SS | 6-bolt 6″ x 6″ | 4,500 | 2,800 | Commercial, Industrial |

| Embedded Standard | 304 SS | 8″ x 8″ embed | 3,500 | 2,200 | New Construction |

| Marine Heavy Duty | 316L SS | 8-bolt 8″ x 8″ | 6,000 | 3,800 | Coastal, Chemical Plants |

| Adjustable Height | 316L SS | 6-bolt adjustable | 4,000 | 2,500 | Renovation Projects |

Installation Time & Cost Analysis

| Project Type | Standard Plates | Heavy Duty System | Time Savings | Cost Impact |

|---|---|---|---|---|

| Residential Deck | 45 min/post | 25 min/post | 44% faster | 15% labor reduction |

| Commercial Stair | 60 min/post | 35 min/post | 42% faster | 20% labor reduction |

| Industrial Platform | 90 min/post | 55 min/post | 39% faster | 25% labor reduction |

| Marine Installation | 120 min/post | 75 min/post | 38% faster | 30% labor reduction |

Real-World Applications & Performance Results

Commercial Heavy Duty Plate Components in Action

Office Complex Renovation in downtown Seattle required 240 base plates for interior stair railings across 12 floors. Standard plates would have needed custom drilling for existing anchor points, adding 3 weeks to the schedule. Adjustable height heavy duty base plates compensated for construction variations, completing installation in original timeframe. Total labor savings exceeded $15,000.

Manufacturing Facility Upgrade specified industrial base plate systems ODM for chemical processing areas. 316L construction withstands daily washdowns with caustic cleaners that destroyed previous carbon steel hardware within 18 months. After 5 years, no maintenance required beyond scheduled inspections.

Coastal Resort Project used marine grade heavy duty mounting systems for 500 feet of oceanfront balcony railings. Previous aluminum hardware failed within 3 years due to salt corrosion. 316L heavy duty base plates show no degradation after 7 years of direct salt spray exposure.

Residential Success Stories

Multi-Unit Housing Development standardized on modular heavy duty base plate systems for 120 units. Bulk purchasing reduced material costs 18%, while standardized installation cut labor time 35%. Maintenance calls dropped to near zero compared to mixed hardware systems.

Historic Building Restoration required code-compliant railings without damaging original masonry. Surface-mount heavy duty base plates distributed loads safely across aged concrete, meeting current IBC requirements while preserving architectural integrity.

Industrial & Infrastructure Projects

Water Treatment Facility demanded corrosion-resistant mounting for elevated walkway systems. Custom heavy duty manufacturing provided 316L base plates with specialized coatings for chlorine resistance. System operates maintenance-free after 4 years in 24/7 chemical environment.

Shipping Terminal Expansion specified heavy duty base plates for 2,000 feet of safety railings exposed to salt air and mechanical abuse. Standard hardware typically requires replacement every 2-3 years. Current installation shows minimal wear after 6 years.

▶ Discuss Your Project Requirements ◀

Installation Support & System Integration

Modular Design Advantages

Heavy duty base plates integrate with standardized post, rail, and infill components for complete railing systems. Pre-engineered connections eliminate field welding and reduce skilled labor requirements. Standard bolt patterns work with multiple post configurations, simplifying inventory management.

Installation Reality Check: Most base plate problems stem from inadequate substrate preparation or incorrect anchor selection. Our installation guides specify drilling procedures, anchor types, and torque requirements for different applications. Technical support helps troubleshoot field conditions that don’t match standard specifications.

Quality Control & Manufacturing Precision

Dimensional Accuracy maintains ±0.005″ tolerances on critical dimensions. CNC machining ensures consistent hole patterns and flatness across production runs. Parts fit correctly the first time, eliminating field modifications that waste time and compromise strength.

Material Certification includes mill test reports for all stainless steel components. Chemical analysis and mechanical properties meet or exceed ASTM specifications. Traceability documentation supports code compliance inspections.

Pre-Delivery Inspection verifies finish quality, dimensional accuracy, and completeness. Packaging prevents damage during shipping and provides organized delivery to job sites.

▶ Connect with Technical Support ◀

Frequently Asked Questions

Q: How do I select between 304 and 316L stainless steel for base plates?

A: Use 304 stainless for interior applications and mild exterior environments. Upgrade to 316L for coastal areas (within 5 miles of salt water), chemical processing, pool decks, or anywhere chlorides are present. The material cost premium typically adds 15-25% but prevents premature replacement.

Q: What’s the real installation time difference between standard and heavy duty systems?

A: Heavy duty base plates typically install 30-40% faster due to fewer anchor points and pre-engineered connections. A standard residential post might take 45 minutes including layout, drilling, and hardware installation. Heavy duty systems average 25-30 minutes per post with better alignment accuracy.

Q: Can heavy duty base plates work with existing railing components?

A: Most systems use standard bolt patterns compatible with common post designs. However, load ratings depend on the complete assembly. We provide compatibility charts and can analyze mixed systems to ensure code compliance and safety factors.

Q: What maintenance do heavy duty base plates actually require?

A: Stainless steel systems need visual inspection every 2-3 years and periodic cleaning in contaminated environments. Check anchor bolt torque annually in high-vibration areas. Most installations require no maintenance beyond cleaning for 15+ years when properly specified.

Q: How do heavy duty base plates handle building movement and settling?

A: Adjustable systems accommodate up to 2 inches of differential movement through threaded leveling mechanisms. Fixed plates require proper expansion joint placement in long runs. Our engineering team helps specify appropriate systems based on building type and local conditions.

Q: What’s the inventory strategy for contractors and distributors?

A: Stock high-volume configurations (4-bolt and 6-bolt surface mount) in 304 stainless. Keep 316L options for coastal markets. Adjustable systems work for renovation specialists. We provide inventory analysis based on your typical project mix and can drop-ship specialty items when needed.

Performance Comparison & Selection Guide

Heavy Duty Base Plates vs. Standard Mounting Hardware

| Feature | Standard Plates | Heavy Duty Systems | Engineered Anchors | Cast-in-Place |

|---|---|---|---|---|

| Initial Cost | Lowest | Moderate | Higher | Highest |

| Installation Time | Baseline | 30-40% faster | Variable | New construction only |

| Load Capacity | Limited | High | Very High | Highest |

| Adjustment Range | None | Up to 2″ | Limited | None |

| Corrosion Resistance | Fair | Excellent | Good | Excellent |

| Maintenance Requirements | High | Low | Moderate | Very Low |

| Code Compliance | Basic | Engineered | Engineered | Engineered |

“Standardized heavy duty mounting systems reduce installation variability and improve long-term reliability compared to field-fabricated solutions.” —National Association of Architectural Metal Manufacturers

“Proper base plate selection and installation prevents 75% of railing system failures in the first five years.” —International Code Council Building Safety Journal

▶ Get Project-Specific Recommendations ◀

Why Choose Engineered Solutions

After 23 years of manufacturing experience, we’ve seen how small details make huge differences in project success. Heavy duty base plates represent the foundation of reliable railing systems—literally. Contractors who invest in proper mounting hardware avoid callbacks, reduce installation time, and build reputations for quality work.

Our heavy duty base plate systems solve real problems: code compliance issues, installation delays, maintenance costs, and performance failures that damage business relationships. Whether you’re specifying marine grade heavy duty mounting for coastal projects or need custom heavy duty manufacturing for unique applications, we provide engineered solutions backed by decades of field experience.

The difference between adequate and exceptional railing systems starts with the foundation. Choose heavy duty base plates that work as hard as you do.