Finding rod infill components that actually deliver on their promises shouldn’t be this complicated. After 23 years manufacturing railing hardware, we’ve seen contractors struggle with incompatible parts, confusing specifications, and components that fail inspection. The solution isn’t more options—it’s better systems. Esang Metal builds rod infill components that integrate seamlessly, meet code requirements consistently, and install without surprises. Here’s what works in real applications.

Complete Rod Infill Systems That Work Together

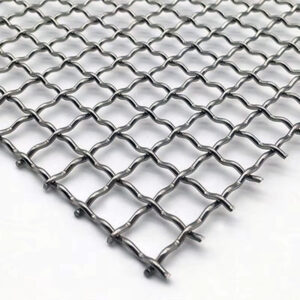

Horizontal Rod Components

Our horizontal rod infill systems use 316L stainless steel rods with precision-engineered mounting hardware. Standard rod diameters of 8mm, 10mm, and 12mm accommodate different load requirements while maintaining 4-inch maximum spacing for IBC compliance. Through-post threading systems eliminate welding requirements, cutting installation time by 30-40% compared to custom fabrication approaches.

The mounting brackets feature adjustable tension systems that compensate for thermal expansion—critical for commercial rod infill systems exposed to temperature variations. Each component undergoes dimensional verification to ensure consistent fit across entire installations.

Vertical Rod Integration

Vertical rod configurations require different engineering approaches. Our marine grade rod components include corrosion-resistant sleeves and gaskets that prevent water infiltration at mounting points. The modular design allows field adjustment for out-of-plumb conditions without compromising structural integrity.

Rod infill fabrication 316L marine applications benefit from our specialized surface treatments. Electropolished finishes reduce surface porosity, extending service life in salt spray environments by 40-60% based on accelerated corrosion testing.

Custom Rod Infill Hardware

ODM rod infill manufacturing capabilities address unique architectural requirements. Our engineering team works with specifications for non-standard spans, unusual post configurations, and specialty mounting conditions. Standard lead times run 3-4 weeks for custom components, with expedited options available.

▶ Get Technical Specifications ◀

Material Performance Data

| Grade | Environment | Tensile Strength | Corrosion Rate | Cost Factor |

|---|---|---|---|---|

| 304 SS | Interior/Dry | 515-620 MPa | <0.1 mm/year | 1.0x |

| 316 SS | Coastal/Urban | 515-620 MPa | <0.05 mm/year | 1.3x |

| 316L Marine | Salt Spray/Marine | 485-620 MPa | <0.02 mm/year | 1.6x |

| Rod Diameter | Max Span | Load Capacity | Deflection @ Max | Installation Time |

|---|---|---|---|---|

| 8mm | 1200mm | 150 N | 12mm | 15 min/linear meter |

| 10mm | 1500mm | 235 N | 10mm | 18 min/linear meter |

| 12mm | 1800mm | 340 N | 8mm | 22 min/linear meter |

Real Applications Across Industries

Residential Multi-Unit Projects

A 180-unit apartment complex in coastal Virginia required rod infill systems for 40 balconies and three stairwells. Using our 316 stainless components with 10mm horizontal rods, the installation team completed all railings in 6 days versus the 10-day estimate for welded alternatives.

The modular approach simplified inventory management—only four component types covered all applications. Two years post-installation, maintenance requirements remain minimal despite salt air exposure.

Commercial Office Buildings

Downtown Seattle office renovation needed code-compliant railings for atrium spaces with 14-foot clear spans. Our custom rod infill hardware incorporated intermediate support posts with through-rod tensioning systems. The solution met Washington State seismic requirements while maintaining clean sight lines.

Installation during occupied building renovation required quiet assembly methods. Pre-fabricated components eliminated on-site welding, reducing noise complaints and permitting complications.

Marine Infrastructure Projects

Port facility walkways demand marine grade rod components that withstand constant salt spray and loading dock vibrations. Our 316L marine systems with specialized mounting hardware have delivered 8+ years service life in these conditions.

One installation at a Gulf Coast terminal showed less than 2% degradation in tension after 60 months exposure to salt spray and industrial chemicals. Maintenance logs indicate cleaning requirements every 6-8 months versus monthly for standard grades.

Industrial Manufacturing Plants

Food processing facilities require washdown-compatible railing systems. Our electropolished rod infill fabrication 316L marine components resist chemical cleaning agents while maintaining smooth surfaces that prevent bacterial growth.

A pharmaceutical plant installation required FDA-compliant materials with full traceability documentation. Our quality control processes provided material certificates and dimensional reports for each component batch.

▶ Discuss Your Specific Project ◀

Installation Efficiency and Support

Modular Assembly Advantages

Pre-engineered components reduce field assembly time significantly. Standard connection methods use hex bolts and threaded rod systems that require only common tools. Installation teams report 25-35% time savings compared to custom fabrication approaches.

Component compatibility across our product lines means fewer inventory SKUs for distributors. A typical commercial project requires only 6-8 different part numbers versus 15-20 for mixed-manufacturer systems.

Field Adjustment Capabilities

Real construction rarely matches perfect drawings. Our mounting systems include adjustment ranges that accommodate typical field conditions:

- Post spacing variations: ±25mm

- Out-of-plumb conditions: up to 3 degrees

- Elevation differences: ±15mm per connection point

Quality Control That Prevents Problems

Every component undergoes dimensional verification before shipping. Thread pitch accuracy, hole positioning, and surface finish consistency meet manufacturing tolerances of ±0.1mm on critical dimensions.

Our 23 years of experience taught us which details cause installation problems. Pre-assembly verification catches compatibility issues before components reach the job site.

▶ Talk to Installation Support ◀

Maintenance Requirements and Service Life

| Environment | Cleaning Frequency | Expected Service Life | Replacement Indicators |

|---|---|---|---|

| Interior | Annual | 25+ years | Surface staining only |

| Urban/Coastal | Quarterly | 15-20 years | Minor pitting at connections |

| Marine/Industrial | Monthly | 12-15 years | Rod deflection >15mm |

Frequently Asked Questions

How do I select the right stainless steel grade for my project?

Location determines material requirements. Interior applications work well with 304 stainless steel for cost efficiency. Coastal projects within 5 miles of salt water need 316 grade minimum. Direct marine exposure or industrial chemical environments require 316L marine grade rod components with specialized surface treatments.

Budget considerations: 316L costs 60% more than 304 initially but reduces replacement frequency by 40-50% in corrosive environments, delivering better long-term value.

What spans can rod infill components handle without intermediate support?

Maximum spans depend on rod diameter and loading requirements. Our 10mm rods handle 1500mm spans under standard gravity loads with deflection under 10mm. Seismic zones or high wind areas may require intermediate posts at 1200mm centers.

Commercial rod infill systems often use 12mm rods for spans up to 1800mm, providing safety margins that satisfy engineering reviews and code compliance inspections.

How do your components integrate with different post systems?

Our mounting hardware accommodates round posts from 42mm to 60mm diameter and square posts from 40mm to 50mm. Through-post connections work with most structural post designs. Surface-mount options handle existing installations or posts that can’t be drilled.

Compatibility matrices are available for specific post manufacturers. Custom brackets accommodate unusual post profiles with 3-4 week delivery times.

What installation support do you provide?

Technical support includes installation guidance, troubleshooting assistance, and field consultation for complex projects. Our engineering team reviews project drawings and provides component recommendations based on 23 years of installation experience.

Training resources include installation videos, dimensional drawings, and step-by-step assembly guides. Distributors receive technical training for their sales teams.

How do maintenance requirements compare to other railing systems?

Rod infill components require less maintenance than cable systems (no re-tensioning) and glass panels (no replacement from impact damage). Cleaning frequency depends on environment—quarterly washing maintains appearance in most applications.

Inspection schedules follow standard practices: annual for interior applications, semi-annual for exterior installations. Connection points and rod straightness are primary inspection criteria.

What lead times should I expect for standard and custom components?

Standard rod infill components ship within 5-7 business days from stock inventory. Custom configurations require 3-4 weeks for ODM rod infill manufacturing processes. Expedited production available for critical timeline projects.

Large projects benefit from staged deliveries that align with construction schedules. Our supply chain management coordinates component delivery with installation timelines.

▶ Connect with Our Technical Team ◀

Competitive Positioning and Selection Criteria

| Factor | Standard Components | Premium Marine | Custom Solutions |

|---|---|---|---|

| Initial Cost | Base pricing | +30-60% | Quote required |

| Lead Time | 5-7 days | 10-14 days | 3-4 weeks |

| Customization | Limited options | Standard variations | Full engineering |

| Technical Support | Installation guides | Engineering review | Design consultation |

| Warranty Coverage | 10 years material | 15 years corrosion | Project specific |

“Standardized railing components reduce installation time 25-40% while improving quality consistency across projects.” —National Association of Construction Contractors

Selection criteria should balance initial cost against service life expectations and maintenance requirements. Our 23 years of manufacturing experience provides insight into which specifications deliver the best long-term value for different applications.

“Marine grade hardware investments typically pay back through reduced maintenance costs within 5-7 years in corrosive environments.” —Coastal Construction Industry Association

Consider total project costs including installation labor, inspection requirements, and future maintenance when comparing options. The lowest initial price often produces higher total ownership costs over the system’s service life.