Finding reliable commercial interior rails isn’t about browsing catalogs—it’s about getting systems that meet codes, install efficiently, and perform consistently. After 23 years manufacturing stainless steel railing components, we’ve learned what contractors and facility managers actually need: modular systems with predictable installation times, clear material specs, and support that solves real problems. Esang Metal builds commercial interior systems that work in the field, not just on paper.

Complete Commercial Interior Rail Systems

Handrail Systems for Every Configuration

Commercial interior rails start with handrail systems that handle real-world mounting challenges. Wall-mounted continuous rails work for corridors and stairways with solid backing. Post-mounted systems handle open areas where wall attachment isn’t feasible. Surface-mounted brackets accommodate existing structures without major modifications.

Material Selection That Makes Sense:

- 304 stainless steel for standard interior environments—cost-effective with excellent corrosion resistance

- 316 stainless steel for areas with chemical exposure, frequent cleaning, or coastal proximity

- Brushed finish provides durability with easy maintenance

- Mirror polish for high-end applications requiring enhanced aesthetics

Commercial interior fabrication 304 stainless offers the best balance of performance and cost for most interior applications. The material handles standard cleaning chemicals, maintains appearance over time, and meets building code requirements for strength and durability.

Railing Posts and Structural Components

Commercial interior systems require posts that handle actual loads while simplifying installation. Standard post configurations include floor-mounted, core-drilled, and surface-mounted options. Adjustable components accommodate field variations without custom fabrication.

Key specifications include:

- Post spacing engineered for 200-pound concentrated load per IBC requirements

- Standard heights: 36″, 42″, and custom options for specific applications

- Mounting hardware designed for concrete, steel, and wood substrates

- Glass panel compatibility with structural calculations provided

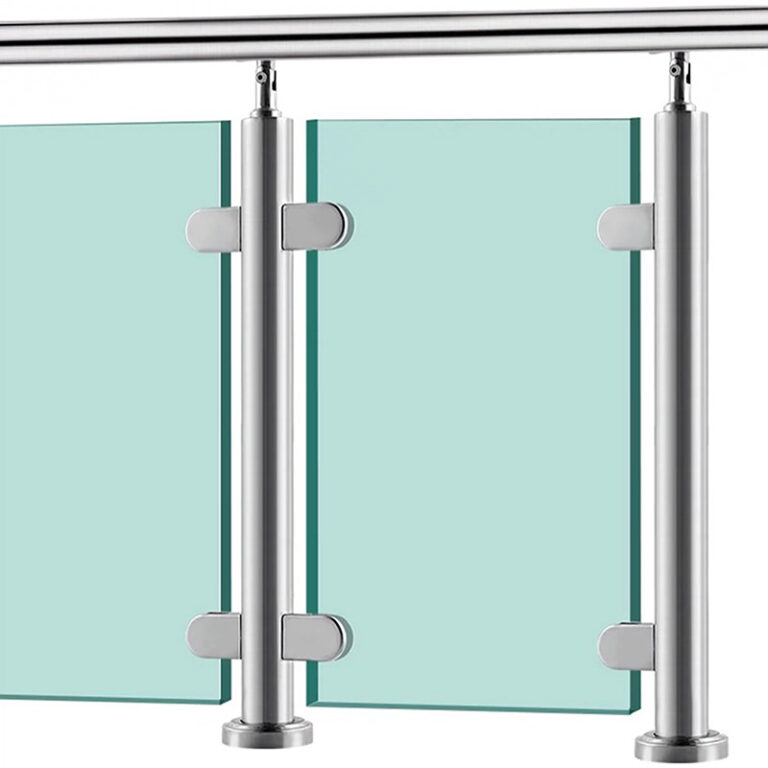

Glass Railing Hardware Integration

Modern commercial interior railing ODM solutions increasingly incorporate glass panels for enhanced visibility and contemporary aesthetics. Glass clamps, spigots, and base shoes integrate with post systems to create seamless installations.

Glass hardware components include:

- Structural glazing clamps for tempered glass panels

- Point-fixed spigots for minimal visual impact

- Base-mounted shoe systems for continuous glass runs

- Gasket systems that accommodate thermal movement

Technical Specifications That Matter

| Component Type | Material Grade | Load Capacity | Installation Method | Typical Applications |

|---|---|---|---|---|

| Wall-Mount Handrail | 304 SS | 250 lbs concentrated | Bracket @ 6′ centers | Corridors, stairwells |

| Post Systems | 304/316 SS | 200 lbs per IBC | Floor/surface mount | Mezzanines, balconies |

| Glass Hardware | 316 SS | Engineered per panel | Point-fix or continuous | Lobbies, offices |

| Cable Systems | 316 SS | 125 lbs per cable | Through-post tension | Modern commercial spaces |

| Installation Timeframes | Standard Projects | Complex Applications |

|---|---|---|

| Handrail Systems | 50-75 linear feet/day | 30-40 linear feet/day |

| Post Installation | 8-12 posts/day | 4-6 posts/day |

| Glass Integration | 20-30 panels/day | 10-15 panels/day |

| Complete Systems | 100-150 sq ft/day | 60-80 sq ft/day |

These timeframes reflect experienced installation crews working with precision commercial components designed for field efficiency.

Real Applications, Measured Results

Office Building Renovations

A 12-story office renovation in downtown Seattle required 2,400 linear feet of commercial interior systems across multiple floors. The project specified 304 stainless handrails with glass panel integration to maintain sight lines while meeting accessibility requirements. Modular component design reduced installation time by 35% compared to custom fabrication estimates. Total installation completed in 18 working days with minimal disruption to occupied floors.

“Standardized components eliminated field measurement errors and reduced our installation timeline significantly.” —Pacific Northwest Contractors Association

Multi-Use Retail Centers

Commercial interior systems in retail environments handle high traffic loads while maintaining appearance over time. A major retail center installation required 1,800 linear feet of railing across three levels, including curved sections and custom height requirements. The precision commercial components approach allowed standard parts to accommodate custom applications through modular connections.

Key performance metrics:

- Installation time: 22% faster than project baseline

- Code compliance: Full IBC and ADA conformance

- Maintenance: Quarterly cleaning only, no component replacement after 3 years

- Budget performance: 8% under allocated costs due to installation efficiency

Healthcare Facility Upgrades

Hospital and medical facility projects demand reliable performance with strict cleanliness requirements. Custom commercial interior manufacturing for a 400-bed hospital expansion included antimicrobial surface treatments and enhanced corrosion resistance for frequent sanitizing.

The project included:

- 3,200 linear feet of continuous handrails in patient corridors

- Glass panel systems for nursing stations and administrative areas

- Specialized mounting hardware for medical equipment integration

- 316 stainless steel in areas with chemical exposure

Installation completed during operational periods with phased approach minimizing patient disruption. All components met healthcare facility requirements for cleanability and durability.

▶ Discuss Your Specific Project Requirements ◀

Installation Support and Technical Assistance

Modular Design Benefits

Commercial interior systems built on modular principles reduce field complexity and installation time. Standard connections eliminate custom fabrication delays. Pre-engineered components arrive ready for assembly with minimal field adjustment required.

Installation advantages include:

- Standard fastener requirements across all components

- Pre-drilled mounting points with established spacing

- Compatibility between different system elements

- Field adjustment capability without compromising strength

Quality Control and Manufacturing Precision

Twenty-three years of manufacturing experience translates to components that fit correctly the first time. Precision commercial components undergo dimensional verification before shipping. Standard tolerances ensure field compatibility across different production runs.

Manufacturing quality measures:

- Dimensional accuracy within +/- 1/32″ on all machined surfaces

- Surface finish consistency across complete orders

- Material certification for all stainless steel components

- Load testing verification for structural elements

▶ Connect with Our Technical Team ◀

Installation Planning and Timeline Management

| Project Size | Planning Phase | Installation Duration | Testing/Approval |

|---|---|---|---|

| Under 500 LF | 2-3 weeks | 1-2 weeks | 3-5 days |

| 500-1500 LF | 3-4 weeks | 2-4 weeks | 1 week |

| Over 1500 LF | 4-6 weeks | 4-8 weeks | 1-2 weeks |

| Complex Custom | 6-8 weeks | Variable | 2 weeks |

Timeline estimates assume standard commercial interior systems with normal permitting processes. Complex projects requiring engineering analysis or custom commercial interior manufacturing may require additional time for design verification and approvals.

Frequently Asked Questions

How do I choose between 304 and 316 stainless steel for interior applications?

304 stainless steel handles most commercial interior environments effectively and costs approximately 15-20% less than 316 grade. Choose 316 stainless for areas with frequent chemical cleaning, swimming pools, coastal buildings, or food service environments. The additional corrosion resistance justifies the higher cost in demanding applications.

What’s the real difference between modular systems and custom fabrication?

Modular commercial interior systems use standardized components that connect in various configurations. This approach typically reduces installation time by 25-40% and provides better inventory management for ongoing maintenance. Custom fabrication offers unlimited design flexibility but requires longer lead times and higher costs. Most projects benefit from modular approaches with selective custom elements where needed.

How do you handle code compliance across different jurisdictions?

Commercial interior systems must meet IBC structural requirements and ADA accessibility standards as baseline requirements. Local jurisdictions may add specific requirements for height, spacing, or materials. We provide engineered drawings and load calculations that address standard code requirements, with modification capability for local variations.

What kind of maintenance do these systems actually require?

Stainless steel commercial interior rails require quarterly cleaning with standard commercial cleaners. Brushed finishes hide minor scratches and maintain appearance better than polished surfaces in high-traffic areas. Moving components like cable tensioners should be inspected annually and adjusted as needed. Well-designed systems typically require minimal maintenance for 15-20 years.

How do you manage inventory for contractors and distributors?

Commercial interior systems benefit from strategic inventory management of high-use components. Standard posts, brackets, and handrail sections can be stocked locally while specialty items ship direct for specific projects. We work with distributors to establish optimal stock levels based on regional demand patterns and typical project requirements.

What’s your approach to delivery scheduling and project coordination?

Precision commercial components require careful delivery timing to avoid job site storage issues while maintaining installation schedules. We coordinate delivery in phases matching installation progress, with critical path components prioritized. Emergency shipments available for unexpected field requirements or damage replacement.

▶ Get Answers to Your Specific Questions ◀

Objective Market Comparison

| Selection Criteria | Standard Fabrication | Import Systems | Modular Domestic | Custom Engineering |

|---|---|---|---|---|

| Initial Cost | Medium | Low | Medium-High | High |

| Installation Time | Standard | Variable | Fast | Slow |

| Quality Consistency | Variable | Variable | High | High |

| Technical Support | Limited | Limited | Good | Excellent |

| Lead Time | 4-6 weeks | 8-12 weeks | 2-4 weeks | 6-12 weeks |

| Code Compliance | Project-specific | Requires verification | Pre-engineered | Guaranteed |

“The key decision factors are project timeline, budget flexibility, and long-term performance requirements.” —National Association of Construction Professionals

Different approaches work better for different situations. Import systems can work for budget-conscious projects with flexible timelines. Custom engineering makes sense for unique architectural requirements. Modular domestic systems like ours provide the best balance of cost, speed, and reliability for most commercial interior applications.

Choose based on your specific priorities: fastest installation, lowest initial cost, best long-term value, or maximum design flexibility. Twenty-three years of experience across thousands of projects gives us perspective on what approach works best for different situations. We’re happy to provide honest guidance based on your specific requirements rather than pushing a single solution.