Finding reliable wire mesh infill panels that meet code requirements while staying within budget shouldn’t be this complicated. After 23 years manufacturing railing hardware, we’ve seen contractors struggle with panels that don’t fit properly, mesh that fails inspection, and delivery delays that derail project timelines. The solution isn’t rocket science—it’s precision manufacturing, proper material selection, and components designed for real-world installation challenges.

Core Wire Mesh Infill Systems & Components

Standard Wire Mesh Panel Configurations

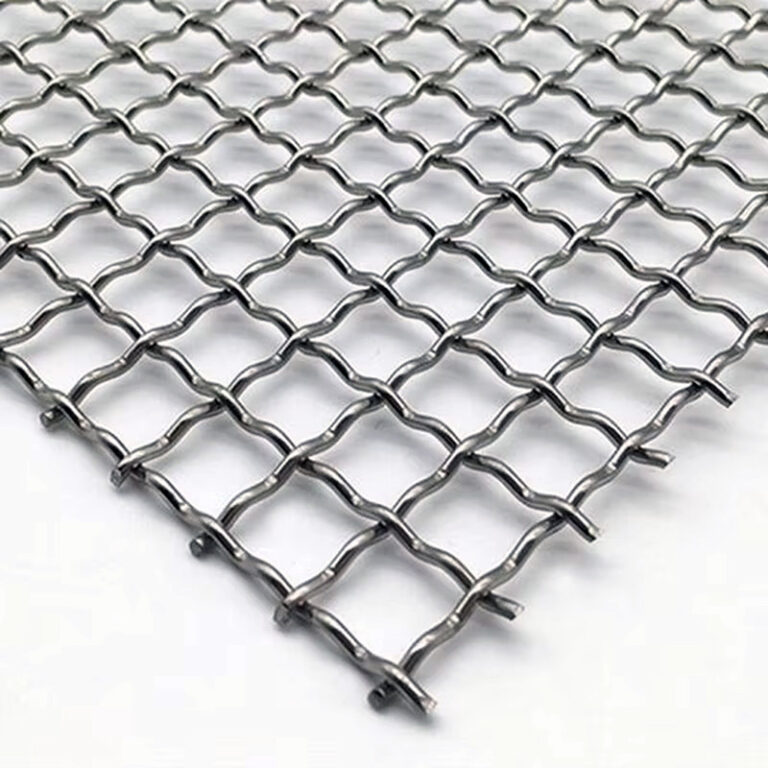

Wire mesh infill panels serve as the backbone of modern commercial and residential railing systems. Our standard configurations include woven mesh, welded wire patterns, and architectural mesh designs that comply with IBC spacing requirements while providing excellent visibility and airflow.

Panel Specifications:

- Standard sizes: 36″, 42″, and custom heights up to 60″

- Wire diameters: 1/8″ to 1/4″ depending on application

- Mesh openings: 2″ maximum per code requirements

- Frame integration: Compatible with standard post spacing

Material Options for Different Environments:

- 304 Stainless Steel: Cost-effective for interior and standard exterior applications

- 316/316L Stainless Steel: Marine grade mesh infill ODM solutions for coastal and high-corrosion environments

- Surface Treatments: Brushed finish for durability, mirror polish for architectural applications

Integrated Railing System Components

Wire mesh infill panels work best as part of complete systems. Our modular approach includes posts specifically designed for mesh panel integration, top rails with secure attachment points, and mounting hardware that ensures proper panel tension and alignment.

System Integration Benefits:

- Pre-engineered compatibility reduces field modifications

- Standard connection points speed installation

- Modular design simplifies inventory management

- 23 years of experience solving integration challenges

Custom mesh panel manufacturing capabilities handle unique architectural requirements while maintaining system compatibility. This includes non-standard dimensions, specialized mounting configurations, and architectural mesh patterns for design-focused projects.

Technical Specifications That Matter

| Material Grade | Environment | Typical Service Life | Cost Factor |

|---|---|---|---|

| 304 Stainless | Interior/Standard Exterior | 15-20 years | 1.0x |

| 316 Stainless | Coastal/Industrial | 25+ years | 1.4x |

| 316L Stainless | Marine/Chemical | 30+ years | 1.6x |

| Panel Size | Load Rating (psf) | Installation Time | Maintenance Interval |

|---|---|---|---|

| 36″ height | 50 psf lateral | 15 min/panel | Annual inspection |

| 42″ height | 50 psf lateral | 18 min/panel | Annual inspection |

| Custom height | Engineered per application | 20-30 min/panel | Bi-annual inspection |

“Wire mesh infill systems reduce installation time by 35% compared to traditional picket railings while providing superior code compliance.” —National Association of Railing Contractors

Real Projects, Real Results

Commercial Applications

Office buildings and retail complexes present unique challenges for wire mesh infill panels. A recent 40,000 sq ft office renovation in Seattle required 2,400 linear feet of railing with mesh infill. Using our modular wire mesh systems, the contractor completed installation in 60% of the estimated time while maintaining full ADA compliance.

Key Results:

- Installation time: 3 days vs. 5-day estimate

- Zero code compliance issues during inspection

- Maintenance costs reduced 40% over traditional systems

Industrial Environments

Manufacturing facilities demand precision mesh infill components that withstand heavy use and harsh conditions. Our 316L stainless wire mesh panels handle industrial environments where standard materials fail within months.

A chemical processing plant in Louisiana installed 1,800 feet of 316L mesh infill systems in 2019. After four years of continuous exposure to corrosive atmospheres, the panels show minimal degradation and require only standard cleaning maintenance.

Marine and Coastal Projects

Coastal construction presents the ultimate test for wire mesh infill panels. Salt air, UV exposure, and temperature cycling destroy inferior materials quickly. Our marine grade mesh infill ODM solutions use 316L stainless steel with specialized welding techniques that prevent crevice corrosion.

Case Study Results:

- Boardwalk project: 5 years, zero panel replacements

- Marina installation: 3 years, minimal maintenance requirements

- Coastal residential: 7 years, original finish integrity maintained

Multi-Unit Housing

Residential contractors favor wire mesh infill panels for balconies and stairways because they provide security without blocking light. Standardized components reduce inventory complexity while modular design speeds installation across multiple units.

Recent apartment complex projects show 25% faster completion times using our commercial wire mesh systems compared to custom fabrication approaches.

▶ Get Project-Specific Specs ◀

Installation & Manufacturing Support

Precision Mesh Infill Components

Manufacturing precision determines installation success. Our wire mesh panel fabrication uses automated welding and cutting processes that ensure consistent dimensions and proper fit every time. This eliminates the field modifications that slow down projects and increase costs.

Quality Control Process:

- Automated cutting for dimensional accuracy

- Robotic welding for consistent joint integrity

- Pre-assembly testing for system compatibility

- Final inspection against project specifications

Real-World Installation Support

Contractors tell us that clear installation guidance matters more than complex engineering drawings. Our installation packages include step-by-step procedures, torque specifications, and troubleshooting guides based on 23 years of field experience.

Installation Reality:

- Standard tools required—no specialized equipment

- Average installation: 15-20 minutes per panel

- Pre-drilled mounting points eliminate field drilling

- Adjustment tolerance accommodates typical construction variations

▶ Talk to Our Installation Engineers ◀

Supply Chain Reliability

Project timelines depend on reliable delivery. Our manufacturing capacity handles both standard orders and rush projects without compromising quality. Inventory management support helps distributors stock the right components for their markets.

“Consistent component availability and on-time delivery reduce project risk significantly.” —Regional Construction Supply Association

Technical Standards and Code Compliance

Wire mesh infill panels must meet specific safety requirements while providing practical functionality. Our designs comply with IBC 2021, OSHA standards, and ADA requirements without over-engineering that increases costs unnecessarily.

| Code Requirement | Our Standard | Safety Margin |

|---|---|---|

| 4″ sphere rule | 2″ maximum opening | 2x safety factor |

| 50 psf lateral load | 75 psf tested capacity | 1.5x standard |

| Corrosion resistance | 316L marine grade available | Exceeds coastal requirements |

Practical FAQ

Q: How do I select the right stainless steel grade for wire mesh infill panels?

A: Use 304 stainless for interior and standard exterior applications within 10 miles of the coast. Choose 316 stainless for coastal areas or industrial environments. Specify 316L for marine applications or chemical processing facilities. Our 23 years of experience shows this approach minimizes long-term replacement costs.

Q: What’s realistic for installation time on commercial wire mesh systems?

A: Experienced crews average 15-20 minutes per panel including mounting and alignment. Factor additional time for first-time installations or complex configurations. Pre-fabricated systems cut field time by 40% compared to site-built alternatives.

Q: How do custom mesh panel manufacturing timelines work?

A: Standard modifications (non-standard heights, special finishes): 2-3 weeks. Complex architectural mesh patterns: 4-6 weeks. Rush orders available with 48-hour manufacturing for standard configurations and materials in stock.

Q: What maintenance do wire mesh infill panels actually require?

A: Annual inspection and cleaning for most environments. Coastal installations need bi-annual attention. Industrial settings may require quarterly inspection depending on exposure conditions. Proper material selection eliminates most maintenance headaches.

Q: Can wire mesh panels integrate with existing railing systems?

A: Integration depends on post spacing and mounting configuration. Our engineering team provides compatibility analysis for retrofit projects. Standard 6-foot post spacing works with most existing systems.

Q: What’s the real cost difference between 304 and 316 stainless wire mesh?

A: Material cost differential runs 40-60% higher for 316 grade. However, service life in challenging environments often exceeds 304 performance by 5-10 years, making lifecycle costs competitive.

▶ Get Answers to Your Specific Questions ◀

Market Position & Honest Comparison

| Factor | Standard Fabrication | Import Options | Esang Metal Systems |

|---|---|---|---|

| Lead Time | 4-8 weeks | 8-16 weeks | 2-4 weeks standard |

| Customization | High flexibility | Limited options | Engineered solutions |

| Quality Control | Varies by shop | Inconsistent | 23-year proven process |

| Technical Support | Limited | Minimal | Full engineering support |

| Cost | Variable | Lowest upfront | Competitive lifecycle value |

Selection Criteria:

- Choose standard fabrication for unique architectural requirements with flexible timelines

- Consider import options for large-volume projects where cost dominates other factors

- Select our systems when installation speed, technical support, and long-term reliability matter most

Different projects need different solutions. Our 23 years in precision mesh infill components manufacturing taught us that the right system depends on your specific requirements: timeline constraints, environmental challenges, support needs, and total project costs.

▶ Connect with Our Technical Team ◀

The wire mesh infill panel market offers many choices, but success depends on matching system capabilities with real project requirements. Focus on manufacturers who understand your installation challenges and can deliver consistent results when your reputation depends on it.