Finding stainless steel u-channels that deliver consistent performance across diverse projects shouldn’t be complicated. After 23 years in manufacturing, we’ve learned that contractors, distributors, and engineers need components that install efficiently, meet code requirements, and provide long-term value without maintenance headaches. The right u-channel systems solve real problems: streamlined installation, predictable inventory management, and proven durability that keeps projects on schedule and within budget.

Comprehensive U-Channel Systems & Components

Structural U-Channel Products

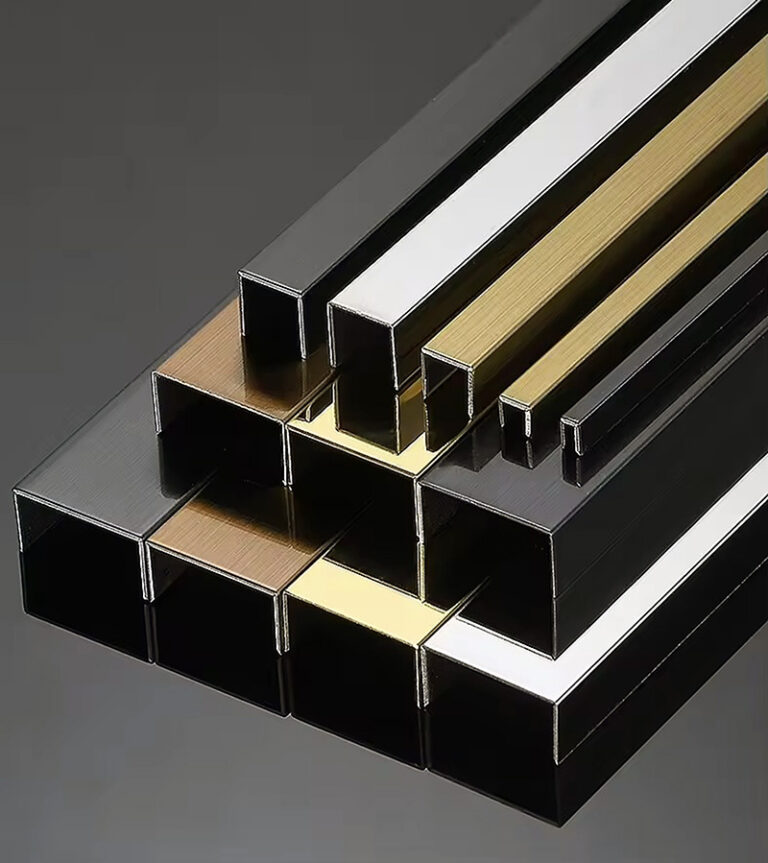

Our stainless steel u-channels serve as essential structural components in railing systems, architectural applications, and custom fabrication projects. Standard profiles include 304 and 316L stainless steel options with consistent wall thicknesses from 1.5mm to 6mm, accommodating load requirements from residential handrails to heavy-duty industrial applications.

Handrail Integration Systems: U-channels designed specifically for handrail mounting provide secure attachment points for wall-mounted, post-mounted, and continuous rail systems. Pre-drilled mounting options reduce field fabrication time while maintaining structural integrity across various installation configurations.

Glass Panel Support Components: Precision-manufactured u-channels for glass railing systems offer secure retention without compromising visual aesthetics. Channel depths accommodate standard glass thicknesses (10mm-19mm) with integrated gasket grooves for weather sealing and vibration dampening.

Post and Rail Connection Hardware: Modular u-channel components facilitate reliable connections between posts, rails, and mounting surfaces. Standardized dimensions ensure compatibility across different system configurations while maintaining load-bearing capacity per current building codes.

Material Specifications & Selection

| Grade | Applications | Corrosion Resistance | Cost Factor |

|---|---|---|---|

| 304 Stainless | Interior, dry exterior | Standard atmospheric | Baseline |

| 316L Stainless | Marine, chemical exposure | Superior chloride resistance | 15-25% premium |

| 316L Marine Grade | Coastal, industrial harsh | Maximum corrosion protection | 25-35% premium |

Surface Treatment Options: Brushed finish (Ra 0.4-0.6μm) provides practical durability for high-touch applications while hiding minor scratches. Mirror polish offers architectural aesthetics but requires more maintenance consideration in heavy-use environments.

Custom U-Channel Manufacturing Capabilities

Twenty-three years of ODM experience enables custom u-channel solutions for unique project requirements. Standard modifications include non-standard dimensions, special mounting configurations, integrated fastening systems, and material combinations that meet specific performance criteria.

Precision U-Channel Components: CNC machining capabilities ensure dimensional accuracy within ±0.1mm tolerances, critical for architectural applications requiring exact fit and finish. Custom hole patterns, slots, and cut-outs integrate seamlessly with existing building systems.

Technical Performance Data

Load Capacity & Structural Requirements

| U-Channel Size | Wall Thickness | Max Load (Distributed) | Deflection Limit | Span Capability |

|---|---|---|---|---|

| 40mm x 40mm | 2mm | 150 lbs/ft | L/240 | 6 feet |

| 50mm x 50mm | 3mm | 250 lbs/ft | L/240 | 8 feet |

| 60mm x 60mm | 3mm | 350 lbs/ft | L/240 | 10 feet |

| 80mm x 40mm | 4mm | 400 lbs/ft | L/240 | 12 feet |

Installation Efficiency Metrics

Standardized stainless steel u-channels reduce installation time through consistent dimensions and pre-engineered mounting solutions. Field feedback indicates 30-40% time savings compared to custom-fabricated alternatives, with reduced material waste and fewer field modifications required.

▶ Get Detailed Technical Specifications ◀

Real-World Application Results

Commercial Stainless U-Channels in Office Buildings

A recent 12-story office project utilized standardized u-channel systems for interior handrails and glass partition mounting. The modular approach reduced installation time by 35% compared to custom fabrication, while standardized inventory simplified procurement across multiple building phases. Total project completion advanced by two weeks through consistent component availability.

Marine Grade U-Channel Systems ODM Projects

Coastal installations demonstrate the value of proper material selection and custom engineering. A waterfront commercial development required 316L marine-grade u-channels with modified mounting configurations for hurricane resistance. Our ODM capabilities delivered custom solutions meeting local wind load requirements while maintaining aesthetic consistency across 200 linear feet of installation.

“Standardized railing components cut installation time up to 40% vs. custom fabrication, with fewer field coordination issues.” —Construction Industry Research Institute

Industrial Applications & Performance Data

Manufacturing facilities require u-channel systems that withstand chemical exposure, frequent cleaning, and heavy use. A pharmaceutical plant installation using 316L stainless u-channels has operated for five years with minimal maintenance, saving approximately $3,000 annually in cleaning and replacement costs compared to alternative materials.

Residential Multi-Unit Housing Solutions

Apartment complexes benefit from standardized u-channel systems that simplify maintenance and ensure consistent safety compliance. One 150-unit development used modular u-channel components across balconies, stairwells, and common areas, reducing inventory complexity by 60% while maintaining code compliance across all applications.

▶ Discuss Your Specific Project Requirements ◀

Installation Support & System Integration

Modular Installation Approach

Pre-engineered u-channel systems eliminate most field fabrication requirements. Standard connection methods use common tools and fasteners, reducing specialized labor needs. Installation guides provide step-by-step procedures with realistic time estimates for different project scales.

Quality Control & Manufacturing Precision

Twenty-three years of manufacturing experience ensures consistent dimensional accuracy and surface quality. Each batch undergoes material certification testing and dimensional inspection before shipment. This precision reduces field adjustment time and ensures reliable fit-up during installation.

| Installation Phase | Standard Time | Tools Required | Crew Size |

|---|---|---|---|

| Layout & Marking | 2 hrs/100 ft | Level, tape measure | 2 person |

| Mounting Preparation | 3 hrs/100 ft | Drill, anchors | 2 person |

| U-Channel Installation | 4 hrs/100 ft | Standard fasteners | 2 person |

| Final Adjustment | 1 hr/100 ft | Level, torque wrench | 2 person |

Supply Chain & Inventory Management

Standard u-channel profiles enable predictable inventory management for distributors and contractors. Batch coordination services align delivery schedules with project phases, reducing on-site storage requirements while ensuring component availability.

▶ Connect with Our Installation Support Team ◀

Frequently Asked Questions

How do I select between 304 and 316L stainless steel u-channels for my project?

304 stainless works well for interior applications and dry exterior environments with normal atmospheric exposure. Choose 316L for coastal locations, areas with chemical exposure, or where superior corrosion resistance justifies the 15-25% cost premium. Marine environments always require 316L grade minimum.

What’s the typical lead time for standard vs. custom u-channel orders?

Standard profile u-channels typically ship within 5-7 business days. Custom configurations require 2-3 weeks for engineering review and production setup. Large quantity orders or non-standard materials may extend lead times to 4-6 weeks.

Can u-channel components integrate with existing railing systems from other manufacturers?

Standard dimensions enable compatibility with most common railing systems. Our technical team reviews existing system specifications to confirm fit and recommend any necessary adaptation hardware. Twenty-three years of experience includes successful integration with numerous different manufacturers’ components.

What maintenance requirements should I expect for stainless steel u-channels?

Routine cleaning with mild detergent maintains appearance and performance. Brushed finishes hide minor scratches and require minimal maintenance. Expected service life exceeds 20 years in most applications with proper installation and periodic cleaning.

How do stainless u-channel fabrication 316L costs compare to alternative materials?

Initial cost runs 25-35% higher than standard steel but eliminates painting, coating maintenance, and replacement cycles. Total ownership cost typically favors stainless steel over 10-15 years through reduced maintenance and longer service life.

What technical support do you provide during installation?

Our engineering team provides installation guidance, reviews project-specific requirements, and troubleshoots field issues. Phone support during installation hours helps resolve questions quickly. This support draws on 23 years of manufacturing and installation experience across diverse project types.

Competitive Analysis & Selection Criteria

Market Position Comparison

| Factor | Esang Metal | Import Alternatives | Domestic Premium | Budget Options |

|---|---|---|---|---|

| Manufacturing Experience | 23 years proven | Variable quality | Higher cost | Limited support |

| Technical Support | Engineering team | Limited availability | Premium service | Basic only |

| Customization | Full ODM capability | Standard only | Available | Minimal |

| Lead Times | 5-7 days standard | 8-12 weeks | 3-5 days | Variable |

| Quality Consistency | ISO certified | Inconsistent | Excellent | Variable |

Selection Criteria for Different Projects

Budget-Conscious Projects: Consider 304 stainless with brushed finish for interior applications. Standard profiles minimize costs while maintaining quality and code compliance.

High-Performance Requirements: 316L marine grade with precision tolerances suits demanding environments. Custom engineering ensures optimal performance for specific conditions.

Fast-Track Schedules: Standard inventory availability and local technical support enable rapid project completion without compromising quality.

“Best railing specs balance performance with long-term cost efficiency, considering installation time and maintenance requirements.” —Building Hardware Association

▶ Get Project-Specific Recommendations ◀

The right stainless steel u-channels solve practical construction challenges through reliable performance, efficient installation, and predictable costs. Our 23 years of manufacturing experience delivers the component consistency and technical support that keep projects on schedule and within budget. Whether you need standard profiles for routine applications or custom solutions for unique requirements, proven manufacturing capabilities and engineering support ensure successful project completion.