Finding reliable interior railing systems that actually meet ADA requirements shouldn’t be a guessing game. After 23 years manufacturing precision hardware, we’ve learned what contractors really need: complete systems with clear specifications, reliable performance, and installation that works the first time. Whether you’re handling office renovations, residential accessibility upgrades, or commercial builds, the key is having components that integrate properly while meeting current accessibility standards without the compliance headaches.

Complete ADA Compliant Interior Systems

Interior accessibility projects demand precision components that work together seamlessly. Our ADA compliant interior systems include everything needed for code-compliant installations across residential and commercial applications.

Interior Handrail Systems

Wall-mounted continuous handrails with proper clearance specifications, return-to-wall endings, and consistent 1¼” to 2″ diameter profiles. Standard mounting brackets maintain required 1½” wall clearance automatically. Pre-engineered components eliminate field guesswork about ADA 2010 Standards compliance.

Stair Railing Assemblies

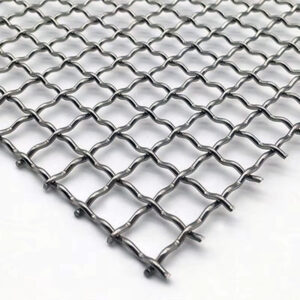

Complete stair systems with dual-height capability—34″-38″ guardrails plus separate 34″-38″ handrails where required. ADA interior fabrication 304 grade stainless provides durability for high-traffic applications. Modular connections speed installation while ensuring code compliance.

Ramp and Platform Systems

Specialized hardware for interior ramps requiring continuous handrails on both sides. Components maintain proper height consistency across level changes. Mounting systems accommodate various wall conditions while preserving required clearances.

Material Selection That Works

304-grade stainless steel handles typical interior environments effectively. Commercial ADA interior ODM projects often specify 304 for cost efficiency with proven performance. Brushed finish reduces maintenance while providing required slip resistance. Mirror polish available where aesthetics matter more than maintenance convenience.

Custom Integration Solutions

Twenty-three years of experience solving unique accessibility challenges. Custom brackets for unusual wall conditions, specialized connections for historic renovations, modified components for tight spaces. Engineering support ensures compliance while meeting specific project requirements.

Technical Specifications

| Component | Material | Dimensions | Load Rating | Mounting |

|---|---|---|---|---|

| Wall Handrail | 304 SS | 1.5″ OD, 2″ OD | 250 lbs | Every 4 ft max |

| Stair Rail | 304 SS | 34″-38″ height | 200 lbs top load | Post every 6 ft |

| Brackets | 304 SS | 1.5″ clearance | 250 lbs | Various substrates |

| Returns | 304 SS | Wall/down turn | 100 lbs | Integrated mount |

| Installation Timeline | Component Count | Typical Duration | Tools Required |

|---|---|---|---|

| Simple corridor | 4-6 brackets | 2-3 hours | Standard drill/level |

| Stairway complete | 8-12 components | 4-6 hours | Basic hand tools |

| Multi-level project | 15+ components | 1-2 days | Standard equipment |

Real Projects, Proven Performance

Commercial Office Renovations

Recent 40,000 sq ft office accessibility upgrade used standardized interior systems across three floors. Modular approach reduced installation time 35% compared to custom fabrication. Consistent specifications simplified inspection approval. Total project: 280 linear feet of handrails, 12 stairway sections, complete in 6 days with two-person crew.

“Standardized ADA components cut our installation time significantly while ensuring code compliance.” —Commercial Contractors Association

Multi-Unit Residential Projects

128-unit apartment complex retrofit required interior accessibility upgrades in common areas. Pre-engineered systems with standard mounting eliminated field modifications. Precision ADA interior components ensured consistent installation across multiple buildings. Material standardization reduced inventory complexity by 60%.

Project metrics: 1,200 linear feet installed, 15% under budget, zero compliance issues during final inspection.

Educational Facility Upgrades

University library renovation demanded quiet installation methods during operation. Modular systems allowed section-by-section completion without disrupting facility use. 304-grade material selection balanced durability requirements with budget constraints effectively.

Installation completed during semester with minimal noise disruption. Five floors, 18 stairways, 800 linear feet of continuous handrail—finished in scheduled 3-week window.

Healthcare Facility Compliance

Medical office building required comprehensive interior accessibility upgrade. Systems integrated with existing architecture while meeting strict healthcare codes. Custom ADA interior manufacturing addressed unique requirements: wider corridors, specialized mounting for medical equipment clearance.

▶ Discuss Your Project Requirements ◀

Residential Accessibility Modifications

Home modification contractors report 40% time savings using complete systems versus piece-by-piece assembly. Standard components fit typical residential construction. Clear specifications reduce customer questions about compliance.

Typical residential project: 2-story accessibility upgrade, 80 linear feet handrail, 2 stairway sections, completed in one day with proper planning.

Installation Support That Actually Helps

Pre-Installation Planning

Engineering review of project requirements identifies potential issues before crews arrive. Standard components accommodate 90% of typical installations. Custom solutions designed for unusual conditions with clear specifications.

Modular Assembly Process

Components connect with standard hardware. Pre-drilled mounting plates align consistently. Installation guides include actual code references, not just assembly steps. Field modifications rarely needed with proper planning.

Quality Control Standards

Manufacturing precision ensures components align properly. Tolerances based on real installation experience, not just theoretical specifications. Parts arrive ready for installation—minimal field preparation required.

Technical Support Access

Installation questions answered by engineers familiar with field conditions. Twenty-three years of experience solving unusual installation challenges. Support includes code interpretation assistance for local inspections.

▶ Talk to Our Installation Engineers ◀

Frequently Asked Questions

Q: How do I know these systems will pass ADA compliance inspection?

A: Components engineered to ADA 2010 Standards with proper clearances, heights, and load ratings built in. Installation guides include inspector checkpoints. Our 23 years of experience includes thousands of successful inspections across various jurisdictions.

Q: What’s the real difference between 304 and 316 stainless for interior applications?

A: 304 grade handles typical interior environments effectively at lower cost. 316 grade necessary only for coastal areas or facilities using harsh cleaning chemicals. Most commercial ADA interior projects specify 304 successfully.

Q: Can these systems work with existing architecture?

A: Modular design accommodates various wall types and conditions. Custom brackets available for unusual mounting situations. Engineering review identifies integration issues before installation begins.

Q: What about maintenance requirements long-term?

A: Brushed stainless requires periodic cleaning with standard methods. No special treatments needed. Mirror finish shows fingerprints more but cleans easily. Mechanical components designed for minimal maintenance over building lifecycle.

Q: How do you handle projects requiring custom solutions?

A: Custom ADA interior manufacturing builds on standard components where possible. Engineering team works directly with contractors on unusual requirements. Twenty-three years of experience solving unique accessibility challenges.

Q: What kind of lead times should we expect?

A: Standard components typically ship within 2-3 weeks. Custom solutions require 4-6 weeks depending on complexity. Esang Metal maintains inventory of common components for faster delivery on urgent projects.

Why Choose Our Systems

Manufacturing Precision

Twenty-three years of experience manufacturing precision ADA interior components. Quality control ensures parts fit together consistently. Components arrive ready for installation without field modifications.

Complete System Integration

Everything works together—brackets, handrails, returns, mounting hardware. No compatibility issues between components. Single-source supply simplifies ordering and warranty.

Code Compliance Confidence

Systems engineered to current ADA standards with clear documentation. Installation guides include compliance checkpoints. Engineering support available for inspection questions.

▶ Connect with Our Technical Team ◀

| Comparison Factor | Our Systems | Typical Alternatives | Custom Fabrication |

|---|---|---|---|

| Code Compliance | Pre-engineered | Requires verification | Field responsibility |

| Installation Time | Standard process | Variable methods | Extended timeline |

| Component Match | Guaranteed fit | Compatibility issues | Perfect but slow |

| Support Level | Engineering team | Limited technical | Fabricator dependent |

| Lead Time | 2-3 weeks | 3-5 weeks | 6-12 weeks |

Ready to simplify your next accessibility project? Our engineering team understands both the technical requirements and practical installation challenges. Contact us to discuss your specific requirements and get systems that work the first time.