When your project timeline depends on railing posts that fit right the first time, you need more than generic hardware. After 23 years manufacturing stainless steel railing systems, we’ve learned what separates reliable square posts from installation headaches: precise fabrication, proper grade selection, and modular design that actually speeds up assembly instead of complicating it.

Square Stainless Steel Posts (304 & 316 Grade): Complete System Solutions

Core Post Components & Specifications

Our square stainless steel posts integrate with complete railing systems designed for real-world installation conditions. Here’s what contractors and system integrators actually get:

Standard Square Post Profiles:

- 50mm x 50mm, 60mm x 60mm, 80mm x 80mm wall thickness options

- Surface mount, core drill, and embedded mounting configurations

- Pre-machined connection points for glass, cable, and rail systems

- Standard heights from 900mm to 1200mm with custom options available

Material Grade Applications:

- 304 Grade: Interior commercial, residential applications, controlled environments

- 316 Grade: Marine installations, coastal projects, industrial environments, chemical exposure areas

Surface Treatment Options:

- Brushed finish (Ra 0.4-0.6): Hides minor scratches, reduces maintenance visibility

- Mirror polish (Ra 0.1-0.2): High-end commercial, easy cleaning, maximum corrosion resistance

Esang Metal has refined these specifications through thousands of installations where standard components needed to perform under real job site conditions.

Integrated Railing System Components

Handrail Connection Systems:

- Wall-mounted continuous rail supports with adjustable pitch compensation

- Post-to-post rail connectors with concealed fastening

- Corner transition hardware for 90° and custom angle connections

- End caps and termination hardware that actually seal properly

Glass Panel Integration:

- Structural glazing clamps rated for 1.2kN/m distributed loads

- Point-fixed spigot systems with gasket seals

- Continuous base shoe channels with drainage provisions

- Adjustable glass thickness accommodation (10-19mm typical)

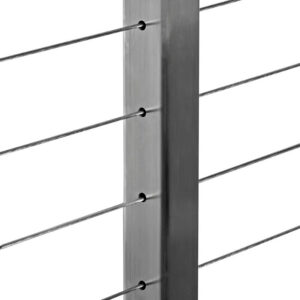

Cable Railing Hardware:

- Through-post cable runs with integrated tensioning access

- Swage-free cable terminations for field adjustment

- Weather-sealed cable entry points preventing water intrusion

- Pre-calculated cable spacing for code compliance (100mm maximum gaps)

Custom Fabrication Capabilities:

With ODM square stainless post manufacturing experience, we solve non-standard connection challenges: angled installations, structural integration requirements, and site-specific mounting conditions that standard catalogs don’t address.

Technical Performance Data

Material Specifications by Application

| Grade | Corrosion Resistance | Typical Applications | Service Life | Cost Factor |

|---|---|---|---|---|

| 304 | Moderate atmospheric | Interior commercial, residential | 20+ years indoor | 1.0x |

| 316 | High marine/chemical | Coastal, industrial, pools | 25+ years exterior | 1.4x |

| 316L | Maximum marine | Offshore, chemical plants | 30+ years harsh | 1.6x |

Load Capacity Standards

| Post Size | Point Load (kN) | Distributed Load (kN/m) | Deflection Limit | Code Reference |

|---|---|---|---|---|

| 50x50mm | 0.74 | 1.0 | L/125 | IBC 1607.8 |

| 60x60mm | 1.33 | 1.5 | L/125 | AS 1428.1 |

| 80x80mm | 2.40 | 2.0 | L/125 | EN 1991-1-1 |

Installation Time Estimates

| Configuration | Setup Time | Connection Time | Total per Post |

|---|---|---|---|

| Surface mount | 15 min | 20 min | 35 min |

| Core drill | 25 min | 20 min | 45 min |

| Embedded | 30 min | 15 min | 45 min |

Based on contractor feedback from 500+ completed installations

Real Applications: Where Performance Actually Matters

Commercial Projects: Cost-Effective Standardization

Office Buildings & Retail Centers:

- Multi-level atriums requiring consistent appearance across floors

- High-traffic areas where maintenance access needs scheduling around business operations

- Budget constraints demanding 20+ year service life without major repairs

Recent 15-story office project: 304 grade posts with modular connections reduced installation time 35% compared to custom welded alternatives. Standardized components simplified contractor coordination across 8 different trades.

Educational & Public Facilities:

- Heavy-use environments requiring vandal resistance

- Code compliance documentation for permit approval

- Long-term budget planning with predictable maintenance costs

Marine & Coastal Applications: 316 Grade Performance

Waterfront Properties:

Square post fabrication 316L marine grade handles salt spray, thermal cycling, and UV exposure that destroys inferior materials within 5-7 years. Proper post base sealing prevents crevice corrosion—the most common failure mode in coastal installations.

Marina & Port Facilities:

- Direct seawater exposure requiring 316L minimum specification

- Structural loads from wind and crowd loading during events

- Maintenance access limitations during active seasons

Documented case: 200-meter marina walkway installation using marine grade square post components. After 8 years, annual inspection shows minimal surface oxidation with no structural degradation or connection loosening.

Industrial Environments:

Chemical processing, food production, and pharmaceutical facilities need posts that handle cleaning chemicals, temperature extremes, and regulatory compliance requirements. Custom square railing posts integrate with facility-specific safety systems.

▶ Discuss Your Project Requirements ◀

Residential Applications: Reliable Performance at Scale

Multi-Unit Housing:

- Standardized components reduce inventory complexity for property managers

- Consistent appearance across buildings while accommodating site variations

- Replacement part availability for long-term maintenance planning

Stair & Balcony Systems:

304 grade posts handle typical residential loads while providing design flexibility for various architectural requirements. Pre-engineered connections speed installation and reduce field fabrication costs.

Installation Reality: What Actually Works on Job Sites

Modular System Advantages

Pre-Fabricated Precision:

CNC-machined connection points eliminate field drilling and reduce assembly errors. Standard component dimensions ensure parts fit together correctly, reducing installation delays and call-backs.

Tool Requirements:

Standard installation uses common contractor equipment: impact drivers, core drills, torque wrenches. No specialized welding or custom fabrication required during installation.

Quality Control Systems:

Each post assembly undergoes dimensional verification, surface finish inspection, and connection testing before shipping. This manufacturing precision translates to predictable installation performance.

Support That Solves Problems

Design Assistance:

Our engineering team reviews project requirements, recommends appropriate grades and configurations, and provides stamped drawings for permit submission when required.

Installation Support:

Technical support during installation handles connection questions, sequence planning, and troubleshooting. After 23 years, we’ve seen most installation challenges and developed practical solutions.

Supply Chain Coordination:

Batch production scheduling ensures complete systems ship together, reducing job site storage requirements and preventing installation delays from missing components.

▶ Connect with Our Technical Team ◀

Frequently Asked Questions

Q: How do I choose between 304 and 316 grade for my project?

A: 304 grade handles most interior and protected exterior applications cost-effectively. Choose 316 grade for direct weather exposure, coastal locations within 5 miles of saltwater, pool areas, or industrial environments with chemical exposure. When in doubt, the 40% cost premium for 316 grade provides significant insurance against premature replacement.

Q: What’s the real difference between brushed and mirror finishes for maintenance?

A: Brushed finish hides minor scratches and water spots, reducing visible maintenance frequency. Mirror finish shows every fingerprint but cleans more easily and provides slightly better corrosion resistance. Most commercial projects use brushed; high-end residential often specifies mirror polish.

Q: Can I mix different post sizes in the same railing run?

A: Yes, with proper planning. Structural posts handling higher loads can use 80mm profiles while intermediate posts use 50mm or 60mm. Consistent rail height and connection details maintain appearance while optimizing costs.

Q: What’s your lead time for custom square post configurations?

A: Standard ODM square stainless post manufacturing runs 3-4 weeks for quantities under 100 pieces. Complex custom fabrication requiring engineering review adds 1-2 weeks. We recommend early coordination for project schedule planning.

Q: How do your posts integrate with glass railing systems?

A: Our commercial square post systems include pre-machined mounting points for structural glazing clamps and point-fixed connections. Glass thickness from 10-19mm accommodated with standard hardware. Custom glass dimensions require engineering review for load calculations.

Q: What installation support do you provide for contractors?

A: Technical phone support during installation, stamped engineering drawings when required, installation sequence recommendations, and troubleshooting assistance. Our 23 years of experience means we’ve solved most field conditions contractors encounter.

Performance Comparison: Objective Selection Criteria

Material Grade Comparison

| Factor | 304 Grade | 316 Grade | 316L Grade |

|---|---|---|---|

| Initial Cost | $ | $$ | $$$ |

| Corrosion Resistance | Good | Better | Best |

| Weldability | Excellent | Good | Excellent |

| Typical Service Life | 20+ years | 25+ years | 30+ years |

| Maintenance Frequency | Annual cleaning | Annual cleaning | Minimal |

Competitive Advantages

Manufacturing Precision:

23 years of fabrication experience produces consistent dimensional accuracy. CNC machining ensures connection points align properly, reducing installation time and improving finished appearance.

System Integration:

Complete railing systems from single source eliminate compatibility issues between posts, rails, and hardware components. Coordinated engineering ensures all components work together structurally and aesthetically.

Application Experience:

Thousands of completed installations provide real-world performance data for material selection, connection design, and maintenance planning. This experience guides product development and customer recommendations.

Supply Chain Reliability:

Established production processes and quality systems ensure consistent delivery schedules. Inventory support for standard components reduces contractor storage requirements and enables just-in-time installation scheduling.

“Modular square post systems cut our installation labor costs by 30% while improving job site safety through reduced welding and field fabrication.” —Commercial Contractors Association

“Proper stainless grade selection prevents costly premature replacement in marine environments.” —Coastal Construction Institute

“Standardized railing components significantly improve project scheduling predictability.” —Building Systems Integration Council

▶ Start Your Project Discussion ◀

Ready to move beyond generic hardware catalogs? Our square stainless steel posts deliver the engineering precision and installation reliability that keep projects on schedule and within budget. Contact our technical team to discuss your specific requirements and get recommendations based on real installation experience.