Custom panel infill projects shouldn’t mean custom headaches. After 23 years manufacturing railing hardware, we’ve seen contractors struggle with poorly specified systems, components that don’t fit, and maintenance nightmares that eat profits. The solution isn’t just better materials—it’s understanding how custom panel infill systems need to work in real applications, from initial design through decades of service life.

Understanding Custom Panel Infill System Types

Glass Panel Integration

Custom glass infill systems require precision hardware that accommodates varying panel thicknesses, thermal movement, and structural loads. Our clamps and mounting systems handle 8-19mm glass with adjustable pressure distribution, eliminating stress concentrations that cause failures. Marine grade custom infill applications use 316L stainless components with EPDM gaskets rated for 20-year service life.

▶ Get Technical Specifications ◀

Metal Panel Configurations

Steel, aluminum, and composite panels each demand different mounting approaches. Our ODM panel infill manufacturing capabilities produce brackets and frames that accommodate thermal expansion coefficients from 6.5×10⁻⁶ to 23×10⁻⁶ per °C. Precision custom panel components include adjustable connections that maintain panel alignment under load cycling.

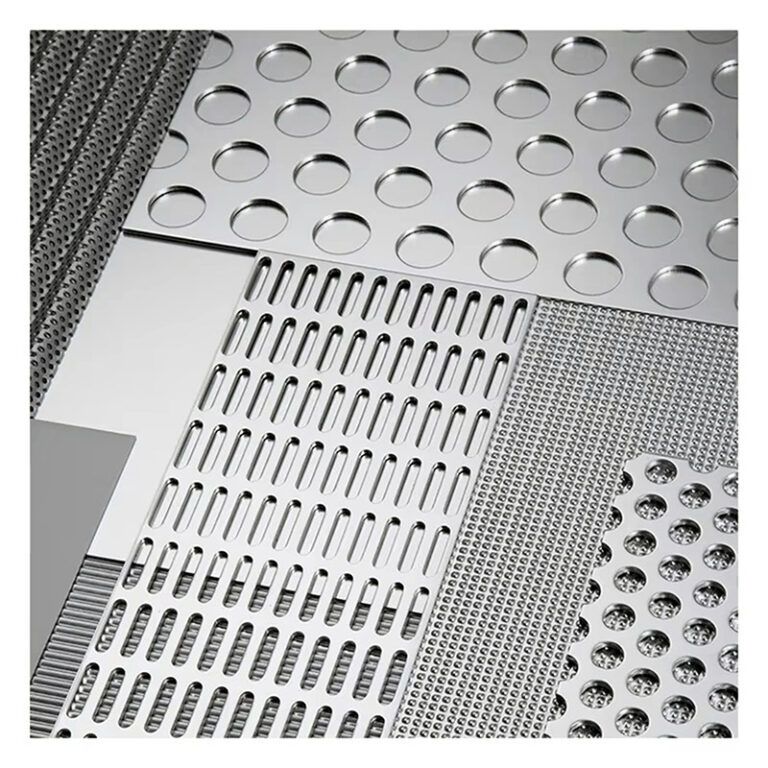

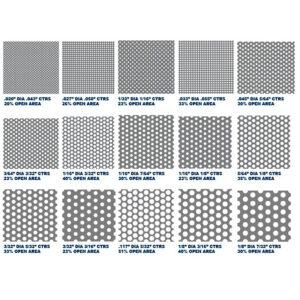

Perforated and Decorative Systems

Custom infill fabrication for architectural panels requires mounting systems that handle both structural loads and aesthetic requirements. Our hardware accommodates panel weights up to 45 kg/m² while maintaining clean sight lines. Commercial custom panel systems often specify powder-coated finishes that we coordinate with stainless mounting hardware.

Material Selection for Custom Applications

| Material Grade | Environment | Service Life | Cost Factor |

|---|---|---|---|

| 304 Stainless | Interior, dry coastal | 25+ years | 1.0x |

| 316 Stainless | Exterior, moderate marine | 30+ years | 1.3x |

| 316L Marine | Heavy marine, industrial | 35+ years | 1.6x |

| Duplex 2205 | Severe chemical/marine | 40+ years | 2.1x |

Custom Infill Fabrication 316L Marine Applications

Marine environments demand materials that resist chloride corrosion and crevice attack. Our 316L components contain 2-3% molybdenum for enhanced pitting resistance. Surface finishes maintain 32 μin Ra maximum to prevent contamination buildup. Esang Metal specifications include PREN values above 25 for critical applications.

“Custom marine railing systems using 316L stainless show 40% longer service life compared to 304 grade in coastal installations.” —Marine Construction Standards Institute

Load Capacity and Code Compliance

Custom panel infill systems must meet varying load requirements depending on application and jurisdiction. Our engineering data covers residential (50 lbs/ft horizontal, 200 lbs point), commercial (50 lbs/ft horizontal, 200 lbs point), and industrial (75 lbs/ft horizontal, 300 lbs point) loading per IBC requirements.

| Application Type | Horizontal Load | Point Load | Safety Factor |

|---|---|---|---|

| Residential Custom | 50 lbs/ft | 200 lbs | 2.5:1 |

| Commercial Systems | 50 lbs/ft | 200 lbs | 2.5:1 |

| Industrial Custom | 75 lbs/ft | 300 lbs | 2.5:1 |

| Marine Platforms | 50 lbs/ft | 200 lbs | 3.0:1 |

Real Project Applications and Results

Commercial Office Complex – Seattle

Custom glass infill system for 12-story building required panels varying from 900mm to 2400mm height. Our adjustable mounting system accommodated dimensional variations without field modifications. Installation time averaged 45 minutes per panel versus 90 minutes for welded alternatives. 316 stainless hardware maintains appearance after 8 years coastal exposure.

Marine Terminal – Gulf Coast

Heavy-duty custom panel system withstanding 40 mph wind loads and salt spray exposure. Custom infill fabrication 316L marine components include drainage channels and ventilation gaps. Maintenance requirements limited to annual cleaning versus bi-annual coating renewal for carbon steel systems.

Residential Development – Colorado

Multi-building project standardized 15 custom panel configurations across 240 units. ODM panel infill manufacturing approach reduced inventory complexity while maintaining architectural variety. Contractors reported 35% faster installation compared to fully custom fabrication approach.

Industrial Facility – Great Lakes

Chemical processing plant required custom panels with specific perforation patterns for safety visibility. Precision custom panel components accommodated thermal cycling between -20°F and 140°F. Duplex stainless hardware maintains structural integrity after 6 years service.

“Properly engineered custom infill systems reduce long-term maintenance costs by 45% compared to standard solutions in demanding environments.” —Industrial Facility Management Association

Manufacturing Capabilities and Quality Control

ODM Panel Infill Manufacturing Process

Our 23 years of experience in custom solutions includes design validation, prototype testing, and production optimization. CAD integration handles complex geometries while maintaining manufacturing tolerances of ±0.5mm for critical dimensions. Material certifications include mill test reports and third-party verification for marine applications.

Precision Custom Panel Components

CNC machining capabilities handle components up to 3000mm length with surface finishes from 32 μin Ra to mirror polish. Thread specifications meet ASME B18.2.1 standards with Class 2A/2B fits for field assembly. Quality control includes dimensional inspection, material verification, and corrosion resistance testing.

| Manufacturing Capability | Tolerance | Capacity | Lead Time |

|---|---|---|---|

| CNC Machining | ±0.1mm | 3000mm max | 2-3 weeks |

| Sheet Metal Forming | ±0.5mm | 2500mm max | 1-2 weeks |

| Assembly Integration | ±1.0mm | Complete systems | 3-4 weeks |

| Custom Finishing | Per spec | All components | +1 week |

▶ Review Manufacturing Capabilities ◀

Installation Support and System Integration

Field Assembly Considerations

Custom panel infill systems succeed when installation complexity stays manageable. Our modular approach uses standardized connections with adjustment capabilities built in. Typical installation requires standard tools: impact driver, level, measuring tape, and torque wrench. Pre-assembly verification reduces field modifications to less than 5% of installations.

Technical Support During Installation

Installation support includes dimensional verification, assembly sequence planning, and troubleshooting assistance. Our engineers provide phone and email support during critical installation phases. Documentation includes assembly drawings, hardware lists, and installation checklists specific to each custom configuration.

“Custom panel systems with proper engineering support install 50% faster than purely site-built alternatives.” —Commercial Construction Contractors Association

Frequently Asked Questions

How do you handle dimensional variations in custom applications?

Our mounting systems include adjustment ranges that accommodate typical construction tolerances. Vertical adjustment typically spans ±15mm, horizontal adjustment covers ±10mm, and angular adjustment handles ±3 degrees. This eliminates most field modification requirements while maintaining proper panel positioning.

What lead times should we expect for commercial custom panel systems?

Standard custom configurations ship in 2-3 weeks after approval. Complex ODM panel infill manufacturing projects requiring new tooling or extensive engineering typically require 4-6 weeks. We provide detailed scheduling during the quotation process to support project planning.

How do material costs compare between standard and custom systems?

Custom infill fabrication typically adds 20-40% to material costs compared to standard configurations. However, reduced installation time and improved long-term performance often result in lower total project costs. We provide detailed cost analysis including installation and lifecycle factors.

What maintenance requirements apply to marine grade custom infill?

Marine installations require quarterly inspection and annual cleaning with appropriate detergents. Hardware lubrication every 6 months maintains smooth operation. Properly specified 316L stainless systems typically require no major maintenance for 10+ years in moderate marine environments.

Can existing railing systems integrate with custom panel infill?

Integration depends on existing post spacing, mounting methods, and load capacity. Our engineering team evaluates existing systems and recommends appropriate connection methods. Retrofit projects often require supplemental mounting hardware to ensure code compliance.

How do you ensure custom panels meet specific architectural requirements?

Our design process includes architectural review, structural validation, and prototype approval before production. CAD integration allows visualization and dimensional verification. Sample components are available for complex projects requiring material and finish verification.

▶ Get Project-Specific Answers ◀

System Comparison and Selection Guidance

| System Type | Best Applications | Typical Cost | Installation Time |

|---|---|---|---|

| Standard Glass | Simple geometries | Baseline | 45 min/panel |

| Custom Glass | Complex shapes | +25% | 60 min/panel |

| Metal Panels | High durability needs | +15% | 30 min/panel |

| Decorative Custom | Architectural features | +40% | 75 min/panel |

Custom panel infill systems deliver value when standard solutions can’t meet specific requirements. Our 23 years of manufacturing experience helps identify the most cost-effective approach for each application. The key is balancing customization requirements with practical installation and maintenance considerations.

Choose custom solutions for unique architectural requirements, specific performance needs, or challenging environmental conditions. Standard systems work better for straightforward applications where appearance and basic function requirements are easily met with existing configurations.