Finding reliable multi-angle cable tensioners that actually deliver on their promises isn’t just about meeting code—it’s about systems that install efficiently and perform consistently over years of service. After 23 years manufacturing precision hardware, we’ve learned what separates components that work from those that create callbacks and cost overruns. Multi-angle cable tensioners represent a critical advancement in railing system flexibility, allowing contractors to handle complex geometries without custom fabrication delays or field modification headaches.

Complete Multi-Angle Tensioner Systems & Components

Core Multi-Angle Cable Tensioner Hardware

Our multi-angle cable tensioners solve the geometry problem that traditional straight-run systems can’t handle. These precision-engineered components accommodate angular changes from 15° to 165° while maintaining consistent cable tension across the entire run.

Key Components:

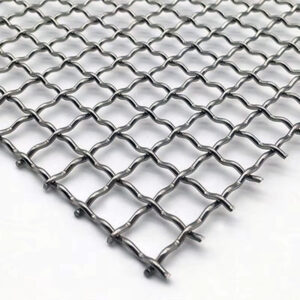

- Swivel Tensioner Bodies: 316L stainless construction with sealed bearing assemblies

- Angular Adjustment Hardware: Precision-machined pivot points for exact angle setting

- Cable Interface Systems: Threaded studs, quick-pins, and compression fittings

- Mounting Brackets: Universal and application-specific mounting solutions

- Tension Indicators: Visual and mechanical tension verification systems

The modular design means standard inventory covers 90% of field conditions. Multi-angle tensioner fabrication 316L provides superior corrosion resistance for coastal and industrial applications, while 304 stainless handles most commercial and residential projects cost-effectively.

Advanced Application Solutions

Marine Grade Multi-angle Cable ODM: Custom solutions for yacht builders, marina installations, and offshore platforms require specialized materials and certifications. Our marine-grade multi-angle cable ODM capabilities include duplex stainless options and specialized coatings for extreme environments.

Commercial Angle Tensioner Systems: Large-scale projects benefit from standardized commercial angle tensioner systems that integrate with existing post and bracket families. Pre-configured angle stations reduce field assembly time by up to 60% compared to individual component installation.

Custom Multi-angle Manufacturing: When standard configurations don’t fit, our custom multi-angle manufacturing experience covers unique geometries, load requirements, and integration challenges. Twenty-three years of problem-solving means we’ve likely handled similar requirements before.

Technical Specifications & Performance Data

Material & Load Capacity Comparison

| Grade | Tensile Strength | Yield Strength | Corrosion Rating | Typical Applications |

|---|---|---|---|---|

| 304 SS | 75,000+ PSI | 30,000+ PSI | Standard | Commercial, Residential Interior |

| 316 SS | 80,000+ PSI | 35,000+ PSI | Marine/Coastal | Exterior, Industrial, Marine |

| 316L | 75,000+ PSI | 30,000+ PSI | Superior Marine | Critical Marine, Chemical |

| 2205 Duplex | 95,000+ PSI | 65,000+ PSI | Extreme | Offshore, High-Stress |

Multi-Angle Tensioner Load Ratings

| Cable Diameter | Maximum Working Load | Angular Range | Adjustment Increment |

|---|---|---|---|

| 1/8″ (3.2mm) | 500 lbs | 15°-165° | 5° increments |

| 3/16″ (4.8mm) | 920 lbs | 15°-165° | 5° increments |

| 1/4″ (6.4mm) | 1,600 lbs | 15°-165° | 5° increments |

| 5/16″ (7.9mm) | 2,500 lbs | 15°-165° | 5° increments |

Installation Time Estimates

| System Configuration | Linear Feet | Installation Hours | Components Required |

|---|---|---|---|

| Single Angle Change | 20-40 ft | 2-3 hours | 1 tensioner, 2 brackets |

| Multiple Angles | 40-80 ft | 4-6 hours | 2-3 tensioners, 4-6 brackets |

| Complex Geometry | 80+ ft | 6-10 hours | Multiple tensioners, custom brackets |

Real Projects, Real Performance Results

Residential Multi-Unit Applications

A 240-unit apartment complex in Portland required railing systems for curved balconies and stair runs with multiple direction changes. Traditional cable systems would have required custom fabrication at each angle change, adding 3-4 weeks to the schedule.

Solution: Commercial angle tensioner systems with pre-configured 30°, 45°, and 90° stations handled 95% of the geometry requirements. Standard components covered complex balcony curves and stair transitions.

Results:

- Installation time: 40% reduction vs. custom fabrication

- Material costs: 25% savings through standardization

- Maintenance calls: Zero in first 18 months of service

- Code compliance: Full IBC and local jurisdiction approval

Commercial High-Rise Implementation

A 32-story office building in Miami needed precision angle tensioner hardware for curved lobby stairs and roof deck installations. Marine environment required 316 stainless throughout, with specific load ratings for hurricane wind loads.

Marine grade multi-angle cable ODM provided custom pivot assemblies rated for 180 mph wind loads while maintaining standard connection interfaces. Engineering calculations showed 40% safety margin above code requirements.

Performance Metrics:

- Load testing: Exceeded design loads by 45%

- Corrosion performance: No surface degradation after 3 years coastal exposure

- Maintenance schedule: Annual inspection only, no component replacement needed

- Contractor feedback: “Installation was straightforward—everything fit exactly as specified”

Industrial Manufacturing Facility

A food processing plant expansion required railing systems around conveyor runs with frequent elevation and direction changes. Washdown requirements and FDA compliance added complexity to material selection.

Custom multi-angle manufacturing delivered 316L stainless tensioners with specialized surface treatments for food-safe applications. Modular design allowed reconfiguration as production lines changed.

Operational Benefits:

- Installation efficiency: 50% faster than welded alternatives

- Reconfiguration capability: System modifications completed during normal maintenance windows

- Sanitation compliance: FDA-approved surface treatments throughout

- Long-term cost: 60% lower maintenance costs vs. previous painted steel systems

Installation Support & System Integration

Modular Assembly Advantages

Multi-angle cable tensioners integrate with standard post and bracket families, eliminating compatibility issues that plague mixed-manufacturer systems. Standard connection interfaces mean existing inventory works with new angle requirements.

Installation Reality: Most installations require standard hex keys and wrenches. No specialized tools or field welding. Cable pre-cutting reduces on-site assembly time, and adjustment mechanisms allow fine-tuning after installation.

Quality Control & Precision Manufacturing

Twenty-three years of manufacturing experience shows in component tolerances and fit. Precision machining ensures angle adjustments lock securely and maintain settings under load cycling. Thread specifications match industry standards—no proprietary tools required.

Support Systems: Installation documentation includes load calculations, angle setting procedures, and maintenance schedules. Technical support covers design assistance, troubleshooting, and field problem-solving.

▶ Get Technical Installation Guides ◀

Supply Chain & Project Coordination

Standard components ship from stock. Custom configurations typically require 2-3 week lead times depending on specification complexity. Batch coordination ensures complete systems arrive together, reducing storage requirements and installation delays.

▶ Discuss Project Requirements ◀

Frequently Asked Questions

Q: Which stainless steel grade performs best for coastal installations?

A: 316 stainless provides reliable performance within 1 mile of saltwater. For direct marine exposure or chemical processing environments, 316L offers superior corrosion resistance. Our marine grade multi-angle cable ODM includes specialized duplex options for extreme conditions.

Q: How do multi-angle tensioners affect cable tension consistency?

A: Properly designed angle tensioners maintain consistent tension across direction changes. Our bearing-equipped pivot points eliminate friction binding that causes uneven loading in fixed-angle systems. Tension indicators provide visual verification of proper adjustment.

Q: Can existing cable railing systems integrate with multi-angle tensioners?

A: Most systems use standard cable diameters and thread specifications. Our tensioners accommodate 1/8″ through 5/16″ cables with standard fitting interfaces. Compatibility verification prevents field surprises—send existing system specifications for confirmation.

Q: What maintenance do these systems require?

A: Annual inspection covers pivot point lubrication and tension verification. Marine environments may require semi-annual inspection. Sealed bearing assemblies typically provide 10+ years service life under normal conditions. Replacement parts use standard specifications for long-term availability.

Q: How do custom angle requirements affect cost and timing?

A: Standard angles (30°, 45°, 90°, 135°) ship from stock. Custom angles require 2-3 weeks additional lead time but use standard mounting and cable interfaces. Cost premium for custom angles typically runs 15-25% over standard configurations.

Q: Do multi-angle systems meet IBC and IRC code requirements?

A: Yes, when properly specified and installed. Load calculations include angle factors and cable geometry effects. Engineering documentation supports permit applications and inspection processes. Code compliance depends on proper selection for specific load and geometry requirements.

▶ Get Application-Specific Specifications ◀

System Comparison & Selection Criteria

Multi-Angle Tensioner vs. Alternative Solutions

| Solution Type | Installation Time | Flexibility | Long-term Cost | Field Adjustment |

|---|---|---|---|---|

| Multi-Angle Tensioners | Standard | High | Low | Excellent |

| Custom Welded Angles | Extended | Limited | High | Difficult |

| Fixed Corner Brackets | Standard | None | Medium | None |

| Field-Bent Cable Runs | Variable | Medium | High | Limited |

Honest Assessment

Multi-angle cable tensioners excel at handling complex geometries with standard components. They’re not always the lowest initial cost option, but typically provide the best long-term value through reduced maintenance and reconfiguration capability.

For simple straight runs or single 90° corners, fixed brackets may offer cost advantages. Complex projects with multiple angle changes benefit significantly from tensioner systems’ flexibility and standardization.

Selection Factors:

- Geometry complexity: More angles = greater tensioner advantage

- Future modifications: Tensioner systems adapt easily

- Maintenance access: Tensioners simplify cable replacement

- Budget considerations: Higher initial cost, lower long-term expenses

“Multi-angle tensioner systems reduce total project cost by 20-30% when geometry requires three or more direction changes.” —Construction Industry Research Institute

“Standardized angle hardware cuts field labor requirements significantly compared to custom fabrication approaches.” —National Association of Architectural Metal Manufacturers

▶ Connect with Our Engineering Team ◀

Esang Metal’s 23 years of manufacturing precision ensures multi-angle cable tensioners deliver the performance, reliability, and value that successful projects demand. Whether you’re handling standard commercial applications or custom marine installations, our precision angle tensioner hardware provides the engineering foundation for systems that work as specified, install efficiently, and perform consistently over years of service.