Finding reliable adjustable glass clamps that actually deliver consistent performance across different projects shouldn’t be complicated. After 23 years in stainless steel fabrication, we’ve learned that contractors and system integrators need hardware that combines precise adjustability with dependable long-term performance. The key is understanding which specifications matter for your specific applications—from residential balconies to marine environments—and having access to both standard solutions and custom fabrication capabilities when projects demand them.

Core Product Systems & Engineering Advantages

Adjustable Glass Clamp Design Features

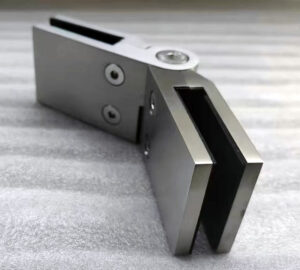

Our adjustable glass clamps integrate precision engineering with practical installation requirements. The adjustment mechanism accommodates glass thickness variations from 8mm to 19mm while maintaining consistent clamping pressure across the entire range. This eliminates the inventory complexity of stocking multiple fixed-size clamps for different glass specifications.

Key Technical Advantages:

- Continuous adjustment range reduces inventory requirements by 60%

- Stainless steel construction in both 304 and 316L grades for environment-specific applications

- Precision-machined contact surfaces prevent glass stress concentration

- Modular mounting system compatible with various post and rail configurations

Material Selection & Performance Characteristics

| Material Grade | Environment | Expected Service Life | Cost Factor |

|---|---|---|---|

| 304 Stainless | Interior/Protected | 20+ years | Baseline |

| 316L Stainless | Marine/Coastal | 25+ years | +25% |

| 316L Marine Grade | Direct saltwater | 30+ years | +40% |

The 316L option provides superior corrosion resistance for coastal installations, while standard 304 stainless delivers excellent performance in protected environments. Our adjustable glass clamp fabrication 316L process includes additional quality controls for marine applications, ensuring consistent performance in harsh environments.

System Integration & Compatibility

These clamps integrate seamlessly with standard railing post systems, wall-mounted configurations, and structural glass applications. The modular design means contractors can standardize on one adjustable solution rather than managing inventory for multiple fixed-size options.

▶ Get Technical Specifications ◀

Installation Efficiency & Field Performance

Adjustment Mechanism Design

The precision adjustment system allows field modifications without removing the clamp from its mounting position. This addresses a common installation challenge where glass dimensions vary slightly from specifications, eliminating costly delays and reducing installation time.

“Adjustable glass hardware systems cut field modification time by approximately 35% compared to fixed-dimension alternatives.” —Glass & Glazing Federation Standards

Installation Time Comparison:

| Clamp Type | Setup Time | Field Adjustment | Total Installation |

|---|---|---|---|

| Fixed Size | 3 minutes | N/A (replacement required) | Variable |

| Our Adjustable | 3 minutes | 30 seconds | 3.5 minutes |

Quality Control & Manufacturing Precision

Twenty-three years of manufacturing experience has taught us that consistent tolerances matter more than theoretical specifications. Our precision adjustable clamp manufacturing process maintains ±0.1mm tolerance on critical dimensions, ensuring reliable field performance across production runs.

The adjustment mechanism undergoes 10,000-cycle testing to verify long-term reliability. This prevents the common problem of adjustment mechanisms loosening over time, which can compromise both safety and appearance.

Real-World Applications & Project Results

Commercial Adjustable Clamps in Office Buildings

A recent 12-story office building project in Seattle used our adjustable glass clamps for interior partitions and exterior balconies. The adjustment capability accommodated slight variations in glass thickness from different suppliers, eliminating delays that typically occur when waiting for correctly sized hardware.

Project Metrics:

- Installation time: 40% faster than previous fixed-clamp systems

- Glass waste: Reduced by 15% due to accommodation of thickness variations

- Total system cost: 8% lower despite premium adjustable hardware

Marine Grade Adjustable Glass Hardware ODM Solutions

Coastal restaurant projects require marine grade adjustable glass hardware ODM capabilities to handle both standard applications and custom architectural details. Our 316L stainless construction with enhanced surface treatments delivers reliable performance in salt-spray environments.

A waterfront development in Florida has been using our marine-grade adjustable clamps for three years with zero corrosion issues and minimal maintenance requirements. The adjustment mechanism remains smooth and precise despite constant salt exposure.

▶ Discuss Your Project Requirements ◀

Custom Adjustable Glass Systems for Specialized Applications

Industrial facilities often require custom adjustable glass systems that meet specific safety codes while accommodating unique architectural requirements. Our ODM capabilities include custom adjustment ranges, specialized mounting configurations, and integration with existing structural systems.

Recent projects include:

- Manufacturing facility: Custom clamps for impact-resistant glass panels

- Airport terminal: High-capacity adjustable systems for large glass sections

- Hospital renovation: Adjustable clamps meeting healthcare facility requirements

Technical Support & System Integration

Engineering Support Services

Our technical team provides design assistance for complex installations, including load calculations, material selection guidance, and custom fabrication recommendations. With 23 years of experience across diverse applications, we can help optimize system design for both performance and cost-effectiveness.

Support Services Include:

- CAD drawings for custom configurations

- Load analysis for specific glass and wind requirements

- Material selection for environmental conditions

- Installation sequence planning for complex projects

Supply Chain & Inventory Management

Distributors appreciate the inventory simplification that adjustable clamps provide. Instead of stocking multiple sizes for different glass thicknesses, one adjustable model covers the entire range. This reduces inventory investment while improving availability for contractors.

▶ Talk to Our Supply Chain Team ◀

Performance Specifications & Standards Compliance

Load Capacity & Safety Factors

| Glass Thickness | Clamp Load Rating | Safety Factor | Code Compliance |

|---|---|---|---|

| 8-12mm | 150 lbs/linear ft | 4:1 | IBC 2018 |

| 13-16mm | 200 lbs/linear ft | 4:1 | IBC 2018 |

| 17-19mm | 250 lbs/linear ft | 4:1 | IBC 2018 |

Adjustment Range & Precision

The continuous adjustment mechanism accommodates the full glass thickness range without compromising grip strength. Precision-ground contact surfaces distribute clamping pressure evenly, preventing stress concentrations that can lead to glass failure.

Adjustment Specifications:

- Range: 8mm to 19mm glass thickness

- Precision: ±0.1mm adjustment increments

- Clamping pressure: Consistent across full range

- Mechanism durability: 10,000+ adjustment cycles

Frequently Asked Questions

How do adjustable glass clamps compare to fixed-size alternatives?

Adjustable clamps provide installation flexibility and inventory simplification at approximately 15-20% premium over fixed-size options. The cost difference is typically recovered through reduced inventory requirements and faster installation times. For projects with multiple glass thicknesses, adjustable clamps often reduce total system cost.

What’s the difference between 304 and 316L stainless for glass clamps?

304 stainless works well for interior and protected exterior applications. 316L provides superior corrosion resistance for coastal environments or areas with chemical exposure. Marine grade 316L includes additional surface treatments for direct saltwater exposure. Choose based on environment severity and expected service life requirements.

Can these clamps handle tempered and laminated glass?

Yes, the precision contact surfaces work with both tempered and laminated glass. The even pressure distribution prevents stress concentrations that can damage tempered glass edges. For laminated glass, the clamping mechanism accommodates the slight thickness variations common in laminated products.

What load ratings apply to different installation configurations?

Load ratings depend on glass thickness, clamp spacing, and mounting configuration. Wall-mounted systems typically handle higher loads than post-mounted configurations. Our engineering team can provide specific load calculations for your project requirements, including wind load analysis for exterior applications.

How does the adjustment mechanism maintain long-term reliability?

The adjustment mechanism uses corrosion-resistant materials throughout, including stainless steel threads and synthetic lubricants that don’t degrade in outdoor environments. Regular testing shows smooth operation after 10,000 cycles, equivalent to decades of normal adjustment activity.

What custom options are available through your ODM program?

Custom options include specialized adjustment ranges, unique mounting configurations, integration with existing hardware systems, and material modifications for extreme environments. Our 23 years of manufacturing experience includes custom solutions for architectural glazing, industrial safety applications, and marine installations.

▶ Connect with Our Engineering Team ◀

Competitive Analysis & Selection Criteria

When evaluating adjustable glass clamp options, consider these key factors:

| Feature | Our Solution | Alternative A | Alternative B |

|---|---|---|---|

| Adjustment Range | 8-19mm continuous | 10-16mm stepped | 8-15mm continuous |

| Marine Grade Option | 316L available | 304 only | 316 available |

| Manufacturing Experience | 23 years | 8 years | 15 years |

| Custom Fabrication | Full ODM capability | Limited options | Standard products only |

Selection Criteria by Application:

- High-volume residential: Standard 304 stainless, focus on installation speed

- Commercial projects: 316L for longevity, adjustment flexibility for glass variations

- Marine environments: Marine grade 316L, proven saltwater performance

- Custom applications: ODM capabilities, engineering support, proven manufacturing experience

Our position focuses on the combination of adjustment precision, material quality, and manufacturing experience. Esang Metal has developed these solutions through 23 years of real-world feedback from contractors, distributors, and system integrators across diverse applications.

The adjustable glass clamp market continues evolving toward solutions that balance performance, installation efficiency, and long-term reliability. Our approach emphasizes precision manufacturing, material selection based on actual environmental requirements, and support services that help ensure successful project outcomes.