Finding ADA compliant wall handrails that actually meet code requirements while delivering reliable performance shouldn’t be a guessing game. After 23 years in the railing hardware business, we’ve learned that contractors and distributors need systems that work right the first time—from initial specification through final inspection. The challenge isn’t just compliance; it’s finding components that install easily, perform consistently, and support long-term project success without breaking budgets.

Complete ADA Railing Systems That Actually Work

Wall-Mounted Handrail Solutions

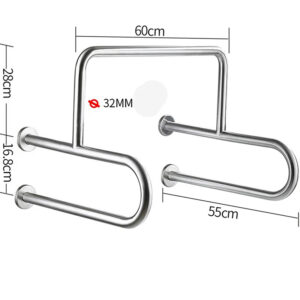

Our wall-mounted systems deliver consistent 1¼” to 2″ gripping diameter with proper wall clearance of 1½” minimum. These aren’t decorative accessories—they’re engineered components built for daily use in high-traffic environments.

Standard Wall Mount Components:

- Continuous rail systems in 8′, 12′, and 16′ standard lengths

- Return-to-wall end configurations for code compliance

- Intermediate brackets spaced per structural requirements

- Extension brackets for uneven wall conditions

Stainless Steel Material Options:

- 304 stainless for interior applications—cost-effective and durable

- 316L stainless for coastal, industrial, or high-moisture environments

- Available in brushed (#4) or mirror polish finishes

The modular design means standard components work together without custom fabrication delays. Contractors tell us this approach typically reduces installation time by 30-40% compared to field-fabricated solutions.

Post-Mounted and Continuous Systems

When wall mounting isn’t practical, our post systems maintain ADA compliance while providing structural flexibility. These systems integrate seamlessly with glass panels, cable infill, or solid railings.

Post System Components:

- Floor-mounted posts with adjustable rail connections

- Wall-return posts for stair applications

- Intermediate posts for extended runs

- Top and side-mounted rail connections

Glass and Cable Integration:

Glass clamps, spigots, and standoffs designed for ADA-compliant top rails. Cable hardware includes through-post tensioning systems that maintain proper rail height while meeting infill requirements.

Custom ADA Compliant Hardware Manufacturing

Twenty-three years of ODM experience means we solve unique compliance challenges through precision manufacturing. Custom brackets, specialized connections, and modified components maintain ADA standards while addressing site-specific requirements.

Technical Specifications for Real Applications

| Component | Material Grade | Dimension Range | Load Rating | Typical Application |

|---|---|---|---|---|

| Wall Rail | 304/316L SS | 1.25″-2″ diameter | 250 lbs concentrated | Interior corridors, stairs |

| Wall Brackets | 304/316L SS | 1.5″-3″ clearance | 250 lbs per bracket | Standard wall mounting |

| Posts | 304/316L SS | 1.5″-4″ diameter | 200 lbs horizontal | Balconies, ramps |

| Glass Clamps | 316L SS | 6mm-19mm glass | 150 lbs per clamp | Commercial glazed systems |

| Installation Timeline | Linear Feet | Standard Components | Custom Elements |

|---|---|---|---|

| Simple wall run | 100 LF | 2-3 days | 4-5 days |

| Stair application | 50 LF | 3-4 days | 5-7 days |

| Complex geometry | 200 LF | 5-7 days | 8-12 days |

Material Performance Data

“316L stainless steel provides 25+ year service life in marine environments with minimal maintenance requirements.” —Stainless Steel Industry Association

| Environment | Recommended Grade | Maintenance Schedule | Expected Service Life |

|---|---|---|---|

| Interior commercial | 304 SS | Annual inspection | 20+ years |

| Coastal/industrial | 316L SS | Semi-annual cleaning | 25+ years |

| High-traffic public | 316L SS | Quarterly maintenance | 20+ years |

Project Applications and Real Results

Commercial and Office Buildings

Office complexes and commercial buildings require consistent ADA compliance across multiple floors and configurations. Our modular systems provide standardization that simplifies specification and installation.

Recent Commercial Project Results:

- 45-story office building: 2,400 linear feet installed in 8 weeks

- Retail complex: Standard components reduced field labor by 35%

- Medical facility: 316L stainless finish maintained appearance through 5 years of high traffic

Multi-Unit Residential Applications

Housing developments benefit from component standardization across multiple units. Standard rail lengths, bracket spacing, and connection details streamline both installation and long-term maintenance.

Residential Performance Data:

- Installation time: 12-15 linear feet per day with two-person crew

- Component standardization reduces inventory needs by 40%

- Consistent quality eliminates callback issues for compliance problems

Industrial and Manufacturing Facilities

Industrial environments demand durability alongside compliance. 316L stainless steel components handle chemical exposure, frequent cleaning, and heavy use while maintaining ADA standards.

“Stainless steel handrails in food processing facilities typically require 50% less maintenance than painted steel alternatives.” —Food Facility Design Association

Marine and Coastal Installations

Saltwater environments require 316L stainless steel for reliable long-term performance. Our coastal installations demonstrate consistent appearance and structural integrity after years of exposure.

Marine Environment Solutions:

- 316L stainless construction standard for all components

- Sealed connections prevent crevice corrosion

- Modular replacement capability for maintenance efficiency

Installation Support and System Integration

Modular Installation Advantages

Pre-manufactured components with standard connections reduce field assembly time and improve installation consistency. Standard bracket spacing, rail connections, and mounting hardware work together as integrated systems.

Installation Efficiency Features:

- Pre-drilled mounting points with template guides

- Adjustable brackets accommodate construction tolerances

- Standard hardware reduces tool requirements

- Clear installation guides with real-world specifications

Engineering and Design Support

Our technical team provides design assistance, load calculations, and specification development backed by 23 years of manufacturing experience. This support helps ensure code compliance while optimizing installation efficiency.

Technical Services:

- ADA compliance verification and documentation

- Structural load analysis and calculations

- Custom component design for unique applications

- Installation troubleshooting and field support

Quality Control Through Manufacturing

Precision manufacturing ensures components fit together correctly without field modifications. This consistency reduces installation delays and eliminates compliance issues from improper fit-up.

“Manufacturing precision in railing components can reduce field installation time by up to 40% compared to custom fabrication approaches.” —Construction Industry Research Board

Frequently Asked Questions

Q: When should I specify 316L stainless steel versus 304 stainless for ADA railings?

A: Use 316L for coastal environments (within 10 miles of saltwater), industrial facilities with chemical exposure, or high-maintenance areas like hospitals and food service. 304 stainless works well for standard commercial and residential interior applications, offering cost savings without performance compromise.

Q: How do I ensure ADA compliance with custom architectural requirements?

A: Start with standard ADA-compliant components, then modify mounting and connection details rather than rail geometry. Our engineering team can verify compliance while accommodating unique design requirements through custom brackets and connections.

Q: What’s realistic for installation timeline on a 500 linear foot project?

A: With standard components and typical conditions, expect 2-3 weeks for installation with a two-person crew. Complex geometry, custom elements, or coordination with other trades can extend this to 4-6 weeks. Pre-installation planning and component staging significantly impacts timeline.

Q: How should distributors approach inventory for ADA railing systems?

A: Focus on standard rail lengths (8′, 12′, 16′), universal wall brackets, and common return fittings. This covers 80% of applications. Custom components can be manufactured to order with 3-4 week lead times for specific projects.

Q: What maintenance should building owners expect with stainless steel ADA railings?

A: Quarterly cleaning with mild detergent maintains appearance. Annual bracket inspection ensures continued structural integrity. 304 stainless typically requires cleaning 2-3 times annually in high-traffic areas. 316L systems often need only semi-annual attention except in harsh environments.

Q: How do these systems integrate with glass or cable railing infill?

A: Our ADA-compliant top rails work with glass clamps rated for 6mm through 19mm glass thickness. Cable systems use through-post tensioning hardware that maintains proper rail height while meeting 4″ sphere requirements for infill spacing.

Market Comparison and Selection Guidance

| System Type | Installation Speed | Cost Level | Maintenance | Best Application |

|---|---|---|---|---|

| Modular Components | Fast | Mid-range | Low | Standard commercial |

| Custom Fabricated | Slow | High | Low | Unique architecture |

| Aluminum Systems | Fast | Low | Medium | Budget projects |

| Painted Steel | Medium | Low | High | Short-term applications |

Why Choose Esang Metal Manufacturing Solutions

Manufacturing Precision: Twenty-three years of stainless steel fabrication experience ensures components meet specifications consistently. This precision reduces field problems and installation delays.

System Integration: Our components work together as complete systems rather than individual parts. This approach simplifies specification, installation, and long-term maintenance.

Technical Support: Engineering assistance, compliance verification, and installation support help ensure project success from design through completion.

Supply Chain Reliability: Established production capacity and inventory management support project schedules without material delays.

Honest Selection Criteria

Choose modular systems for projects requiring fast installation and long-term reliability. Consider custom solutions when architectural requirements demand unique geometry. Evaluate 316L stainless for harsh environments or when 20+ year service life is essential.

Budget-conscious projects may benefit from 304 stainless in appropriate environments. However, maintenance costs over 10-15 years often favor higher initial investment in 316L materials and precision manufacturing.

The right choice depends on specific project requirements, environmental conditions, and long-term performance expectations. Our team can provide objective analysis based on your actual conditions and requirements.